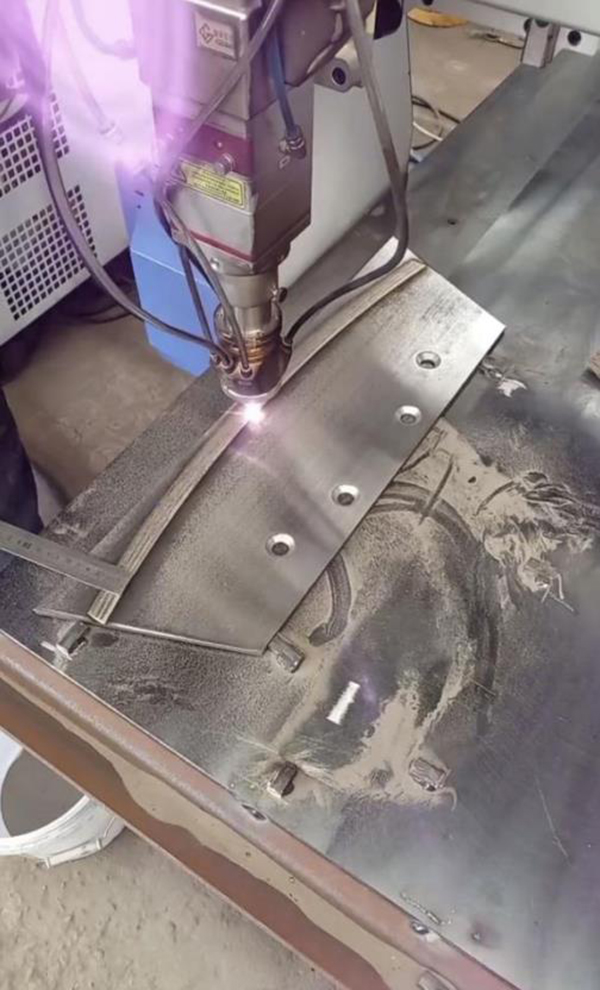

Laser cladding of plane gantry

Advantages of laser cladding

1. Fast cooling speed (up to 106℃ / s), belongs to the fast solidification process, easy to get the fine crystal organization or produce an equilibrium state can not get the new phase, such as unstable phase, amorphous state;

2. The cladding layer and the substrate are strong metallurgical combination or interface diffusion combination, low dilution rate, strong controllability, according to the needs to control the welding focal length, control the depth of welding melting, and then control the dilution rate of welding;

3. The laser cladding reinforcement repair parts have small thermal impact, small deformation, only surface dissolution in the processing process, and the thermal impact area of the base is small, generally between 0.1-0.5mm;

4. The matrix and cladding material are metallurgical combined, and the binding strength is comparable to the base material;

5. The thickness and hardness range of the cladding layer is large, and the cladding layer is dense, with no pores, slag clips, cracks and other defects, and the hardness of the cladding layer can reach 18-60HRC;

6. There are almost no restrictions on powder selection, melting high melting alloy on the low melting metal surface;

7. Laser is suitable for long-distance transmission, and large parts can be repaired on site;

8. Laser cladding has the characteristics of non-contact welding, for some, groove, deep hole cladding welding;

9. Handheld cladding is flexible, and complex shape parts can be repaired smoothly, without the trouble of programming or automation;

Picture display