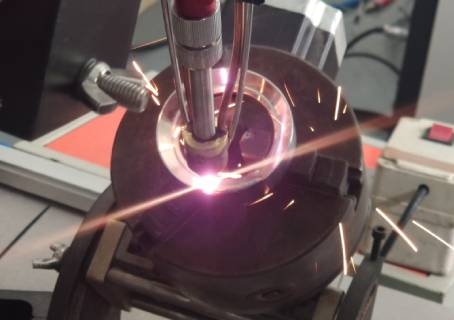

Portable laser cladding welding machine

Laser cladding advantage

1 Cooling swiftly, up to 106℃/s, solidifying swiftly it is easy to get the fine grains microstructure or the cenotype which it can’t form as producing balance.

2 It is possible to control the focus distance and penetration to do the dilution rate, due to the metallurgical Bonding between welding material and base.

3 low heat impact, tiny deformation, only melting on the surface in the course of cladding (0.1-0.5mm)

4 High density of the cladding layer. There is not any shortage of the hole, slag and crack etc, the 18-60HRC

5 Barely limitation to choose the powder, even the high melting point material caldding on the low melting point ones.

6 It is proper for transmission remotely and would repair the huge parts on the spot.

7 It is possible to cladding the in the place of groove, deep hole etc, because it is no need to contact to do for laser cladding.

8 It would be going very well by hand-held laser cladding system to the parts of complex shape, without the trouble of programming.

Picture display