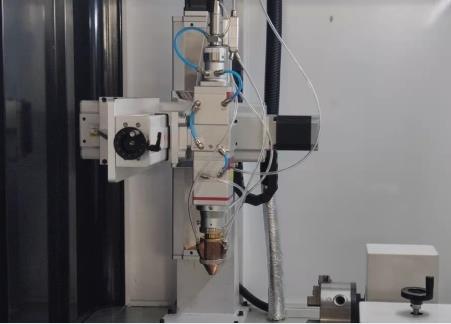

Cutting picks automatic laser cladding equipment

Characteristic

After using the laser cladding technology, the average tooth cut microhardness is HV800, and the Rockwell hardness is about HRC65. Compared with ordinary tackle, the laser has no spark when cladding tackle and coal seam contact, and the wear resistance, fatigue resistance strength and shear resistance are greatly improved. It not only reduces the tooth replacement and maintenance time, improves the production efficiency, but also saves a lot of funds, reduces the cost, and increases the income. Laser cladding technology as an emerging treatment technology, advanced technology, cladding parts after the stable, reliable, lasting, therefore, in the coal machine manufacturing industry should be vigorously promoted and adopt laser cladding technology.

Picture display