TIG welding (Tungsten Inert Gas Welding), also known as GTAW, is a kind of arc welding process using non-fusible tungsten electrodes, protected by inert gas (usually argon). Its main features are high weld quality, clean weld seam, and suitable for high-precision welding of a variety of metal materials.

Development background of TIG welding

originated in the 1940s for the manufacture of aluminum alloy structures for aircraft, and then it was widely used in nuclear energy, shipbuilding, electronics and medical equipment industries, becoming one of the irreplaceable precision welding technologies in modern industry.

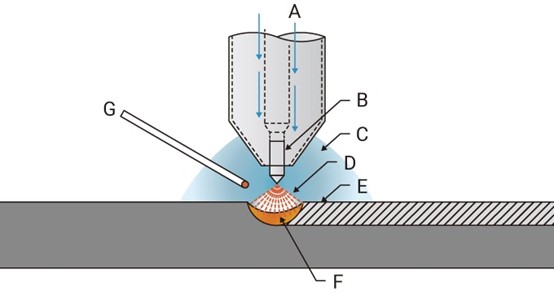

Principle of TIG welding

TIG welding utilizes a DC or AC power source to melt metal through a high-temperature arc generated between a tungsten electrode and the workpiece. Inert gas provides protection against contamination of the weld by atmospheric oxygen and nitrogen.

Equipment Components for TIG Welding

- Power supply unit: constant current DC or AC welder

- Welding gun: including tungsten electrode holder, gas nozzle, water cooling system, etc.

- Tungsten electrode: pure tungsten (W), thoriated tungsten (WT20), cerium tungsten (WC20) and so on.

- Protective gas system: mainly argon, equipped with flow controller and gas cylinders

- Filler metal (optional): welding wire matching the base material.

- Cooling system: high power welding using water-cooled welding torch needs to be equipped with a cooler

TIG welding process parameters and control points

| Item | Parameter range (example) | Control description |

| Current type | Direct current (DC)/AC | AC for aluminum, DC for stainless steel |

| Current size | 15-300A | Depends on board thickness and electrode diameter |

| Gas flow | 8-15L/min | Stable in the room with no excessive gas flow |

| Tungsten electrode diameter | 1.0-4.0mm | Thin electrodes for thin boards |

| Welding torch angle | 10-15° tilt | For gas protection and operating space Favorable |

| Arc length control | 1-3mm | The shorter the arc length, the greater the depth of fusion |

Applicable materials and welding methods for TIG welding

Available materials for TIG welding

- Stainless steel (austenitic type, duplex type)

- Aluminum alloy (6000, 7000 series)

- Magnesium alloy, titanium alloy

- Copper and its alloys

- High temperature alloys (Inconel, Hastelloy)

Several forms of TIG welding

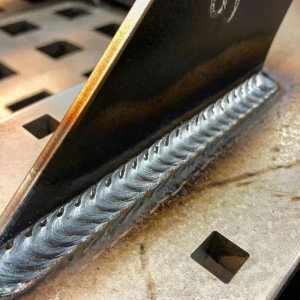

• Butt welding

• Fillet Weld

• TIG tube and plate welding

• TIG single-sided welding and double-sided molding

Advantages and disadvantages of TIG welding

Advantages of TIG welding

- High quality weld, almost no slag and porosity

- Beautiful weld, suitable for visible parts

- Fine control of melt depth and melt width

- No spatter, clean environment

Disadvantages of TIG welding

- Slow welding speed

- High operating requirements

- Higher costs (gas, electrode, water-cooling system)

- Unsuitable for large thicknesses and high output welding

Technical points of TIG welding operation

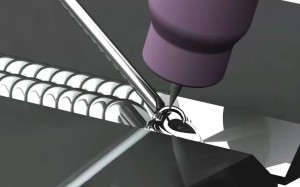

Electrode grinding

- should be sharpened to “pencil point shape”.

- Smooth surface, no burrs

- Keep the grinding direction consistent with the axis

Arc initiation and arc closing

- Arc initiation adopts high-frequency start-up mode to avoid touching the base material.

- Before closing the arc, the gas should be shut off with a delay to ensure that the weld does not oxidize during the cooling process (back gas protection)

Manual Operation Skills

- Stabilize the hand and keep the eyes on the molten pool.

- Move at a uniform speed to avoid jitter

- Synchronized wire feeding, consistent rhythm

Common Problems and Preventive Measures of TIG Welding

| Type of Defect | Possible Causes | Preventive Measures |

| Gas Holes | Insufficient Gas Flow, Contaminants | Keep Gas Pure, Clean Surface of Base Material |

| Cracks | Insufficient Preheating, Cooling Too Fast | Control Cooling Rate, Proper Preheating |

| Failure to Fuse | Low Current, Moving Too Fast | Adjust Current Parameters, Decrease Welding Speed |

| Welding Tumors | Unstable Melt Pool Control, Overfeeding | Improve Handling Skills, Feed the Right Amount of Wire |

Safety and environmental considerations when using TIG welding

- Wear UV-protective mask to prevent arc burns

- Maintain good ventilation to avoid argon gas gathering

- Clean up flammable materials in the operation area to prevent fire

- Use insulated welding gloves, heat protective sleeves

Application case study of TIG welding (brief)

Case 1: stainless steel medical equipment welding

Material: 304 stainless steel

Requirements: weld without porosity, uniform shape

Process: TIG DC welding, low-current control of the depth of fusion, argon protection delay 10s

Results: to meet the requirements of non-destructive testing, the weld does not need to be grinding

Case 2: Aluminum alloy heat exchanger welding

Material: 6061 aluminum plate

Process parameters: AC welding, preheating to 120 ° C, the use of pulse control to prevent burn-through

Results: strength, sealing to meet the test standards

Future trends in TIG welding

- Automation integration: TIG robot system has been widely used in aerospace and medical care

- Intelligent control: Closed-loop control through melt pool image recognition

- High-frequency pulsed TIG: improve the welding efficiency and quality of thin materials

- Multi-material welding technology development: to meet the needs of dissimilar metal connections

Post time: May-29-2025