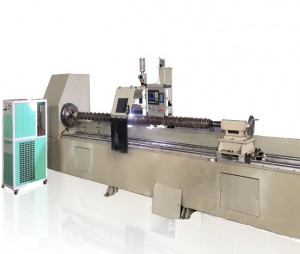

Intelligent EDM cladding repair machine ——ESD-9100

Equipment features

Adopting high performance processor control, no drift of welding parameters, higher quality welding. Memory multi-group data, commonly used material welding parameters can be directly called, the operation is more intelligent and more convenient.Adopting unique chopper soft-switching technology, the output control is precise.Surfacing and surface strengthening are possible. Can weld ferrous metals (ductile iron, grey iron,stainless steel, etc.) Non-ferrous metals (copper, aluminium, magnesium, zinc, etc.) can be welded.

Product Parameter

| Models | ESD-9100 |

| Power | 1000w |

| Frequency | 50-500HZ |

| Input Power | AC220V |

| Voltage ranges | 20-100V |

| Percentage output | 10-100% |

Product Application

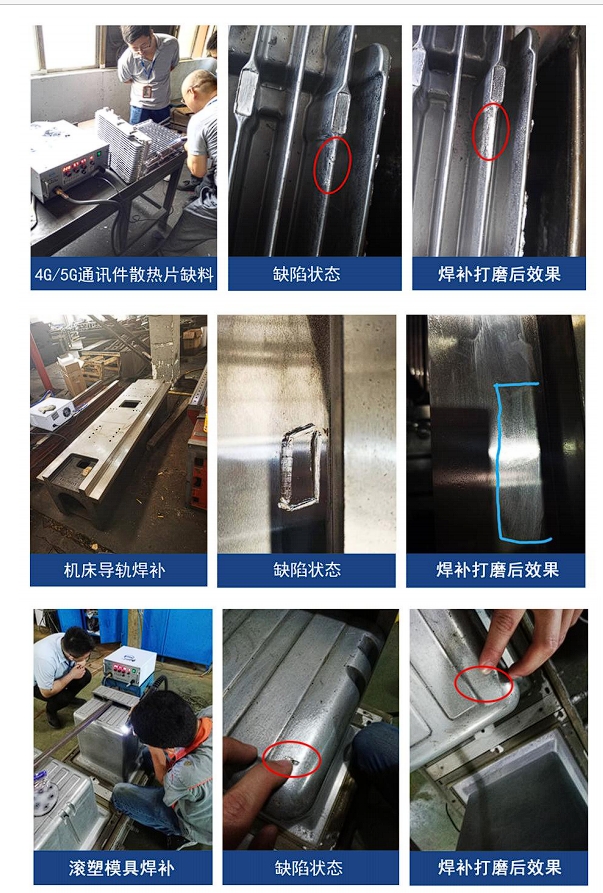

Casting industry

Automotive casting products: automotive crankshafts, pistons, cylinder blocks, intake and exhaust pipes, brake discs and other casting defects, such as sand holes, air holes and so on!Mechanical industry and machine tool industry: correction of excess or wear of the workpiece, such as the repair of machine tool rails, bed, large machinery shafts, teeth parts! Cold and hot rolls for steel rolling, hydraulic rods of engineering machinery, printing press cylinders and other various parts of the welding.Aviation and shipbuilding industry: compressor shells, air compressor shells, non-steel precision parts, precision shafts, and so on. Petrochemical, coal, engineering machinery and many other industries, product repair.

Copper, aluminium, magnesium, zinc and other non-ferrous metal industry

Non-ferrous metal parts for various industries, such as aluminium alloy parts for SF6 transformers in the power industry, aluminium alloy cylinders and cylinder head hubs in the automobile industry, aluminium alloy impellers for fans, aluminium alloy radiators, and so on. Copper alloy plumbing valves, pipe fittings, impellers, turbines and so on.

Mould industry

Casting Mould: Welding and patching of moulds for wear and tear, bruises and scratches. Die casting mould: zinc and aluminium die casting moulds of etching, peeling, damage, etc., as well as the cavity and sprue mouth of the surface strengthening, to extend the service life of the mould.

Copper alloy moulds, aluminium alloy moulds, nitriding moulds and so on.