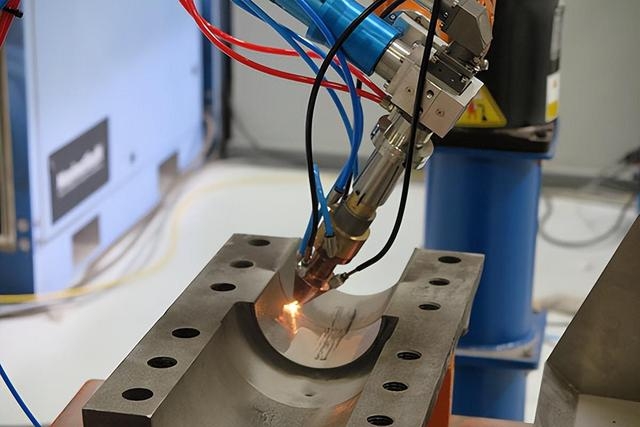

Laser cladding and the process (LMD)

Laser cladding is a process (laser metal depostion)that is very important in the industry, but many people may not know why.

When people who do not work in this business first hear about laser cladding, many will think that it is a technology similar to electroplating or welding.

This idea is part correct, because laser cladding can replace electroplating technology in a certain extent, but in most cases, the use of laser cladding technology is still metallurgical combination, that is, strengthening or repairing collective materials.

This is a bit like the "Enchantment" in online games that young people often play nowadays.

Specific materials can be used to turn into weapons, equipment or other materials with "low qualification" into new equipment with higher level, better effect, better performance or higher value than the original.

In this game, there are many different versions of enchanting, such as inlaying runes, melting gems, embedding crystals, etc. no matter how the name changes, this method is a powerful way for players to improve their own attributes and competitiveness and enhance their own force value.

In real life, the laser cladding technology has similar effects. The original "ordinary" materials or workpieces will be reborn after laser cladding.

The strength, durability, hardness and corrosion resistance will be greatly improved, so that the raw materials and workpieces can be more widely used and can be competent for "posts" with higher basic quality of materials.

More importantly, when laser cladding is used, not only the dilution ratio of cladding material is lower than that of the same type of technology, but also the heat affected area is smaller, which enables more accurate or more precise cladding or repair work, and the deformation of the workpiece after use is smaller.

Because of the above advantages, laser cladding technology can solve many problems that cannot be solved by traditional manufacturing methods. Therefore, it has been supported and promoted by the state. It is an intelligent high-tech with inherent genetic advantages such as high precision, high flexibility, green and openness, and plays an extremely important role in industrial manufacturing upgrading.

The process flow of laser cladding is mainly divided into preset type and synchronous type, wherein:

The main process flow of preset type is:

Surface pretreatment, preset cladding materials, preheating, melting and post heat treatment;

The main process flow of synchronous type is:

Surface pretreatment, melting and post heat treatment.

Post time: Aug-24-2022