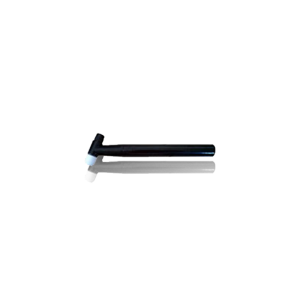

Independently Research And Develop Plasma Surfacing Torch 300

Equipment features

The plasma surfacing torch 300A is decomposed as follows: back cap, tungsten electrode clip, tungsten electrode, torch body, shield gas ring, powder hole ring, water hole ring, central ring, nozzle, locking ring, shielding cover.

Nozzle:The core of the PTA welding torch The powder feeding hole is interspersed inside the nozzle, so that the powder can be fed into the plasma arc without interference, so as to complete the powder cladding.

The channel of circulating cooling water is opened on the nozzle, so that the nozzle is effectively cooled, and the temperature of the nozzle hole wall is reduced, and the gas with a certain pressure entering the spray gun air chamber is closer to the hole wall, and its ionization degree is lower, and it is different from the hole wall. The close cold gas layer is basically not ionized, but becomes a neutral gas, so that a circle of insulating and heat-insulating neutral gas flow layer is formed between the arc and the hole wall, and the arc current is forced to concentrate on the central part of the gas ionization degree. , the shrinkage of the arc Central ring:Keep the center hole of the copper nozzle concentric with the tungsten electrode.

Product Parameters

| Mode | DJPT30018-HQ |

| Main Arc | Water-electricity integration |

| Tungsten electrode-Workpiece | Negative-Positive |

| Mode of Tugsten | 4.8 |

| Arc Voltage | 90V |

| Welding Current | 30-300A 80% temporary load rate |

| Pilot Arc | Water-electricity integration |

| Tungsten-Nozzle | Negative-Positive |

| Pilot Arc Current | 3-20A 100% Temporary load rate |

| Mode Powder feeding | Aggregate |

| Volume Powder feeding | Max. 150g/Min |

| Gas Powder feeding | 1.0-3.0L/min |

| Type Powder | Alloy Powder |

| Size Powder | 70-200um |

| Passage Powder feeding | Duble gas passage |

| Cooling | Circular cooling |

| Ion gas | 0.5-6L/min |

| Shield gas | 5-25L/min |

| Nozzle Cooling | Water cooling directly |

| Diameter Nozzle | 3.0-5.0 mm |

| Length Cable | 5 m (customized avaiable) |