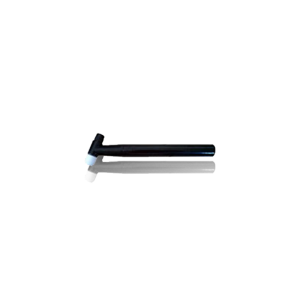

Affordable Plasma Transfer Arc Surfacing Torch 160

The performance of the surfacing gun greatly affects the deposition rate, powder utilization rate, surfacing layer quality and process stability 160A plasma surfacing gun consists of three parts: upper gun body, lower gun body and insulator. Among them, the upper gun body is used to fix and install the tungsten electrode, and connect the water and electric connectors; the lower gun body is used to fix and install the nozzle, and constitute the water cooling cavity of the nozzle, and connect the joints of the water, electricity, gas, and powder pipelines; the insulator ensures that the upper and lower Insulate the gun body and connect and fix the upper and lower gun body . Among them, the protective gas of the gun body completes the gas diffusion inside the gun body to form a uniform protection; the powder feeding pipeline is independently embedded in the gun body to better realize the independence and smoothness of the powder feeding system. 160A plasma surfacing gun is a general-purpose plasma powder surfacing gun independently developed and produced by our company.

The gun body is made of one piece of die-casting, which has better insulation and sealing. It has good stability and safety during the surfacing process. High performance, high surfacing welding efficiency, good quality after welding, long service life of the nozzle, convenient operation, easy to replace, small and flexible, manual, semi-automatic, and automatic welding can be used.

The exploded view of the plasma surfacing gun is as follows: rear cap , tungsten pole clamp, tungsten pole, gun body, protective gas apron, powder hole apron, water hole apron, centering ring, nozzle, locking ring, protective cover.

Product Parameters

| Mode | PT16013-HQ |

| Main Arc | Water-electricity integration |

| Tungsten electrode-Workpiece | Negative-Positive |

| Mode of Tugsten | 3.2 |

| Arc Voltage | 90V |

| Welding Current | 3-160A 80% temporary load rate |

| Pilot Arc | Water-electricity integration |

| Tungsten-Nozzle | Negative-Positive |

| Pilot Arc Current | 3-20A 100% Temporary load rate |

| Mode Powder feeding | Aggregate |

| Volume Powder feeding | Max. 50g/Min |

| Gas Powder feeding | 1.0-3.0L/min |

| Type Powder | Alloy Powder |

| Size Powder | 70-200um |

| Passage Powder feeding | Single gas passage |

| Cooling | Circular cooling |

| Ion gas | 0.5-6L/min |

| Shield gas | 5-25L/min |

| Nozzle Cooling | Water cooling directly |

| Diameter Nozzle | 2.8 mm |

| Length Cable | 4 m (customized avaiable) |