How to hardfacing the seal surface of Valve with PTA welding

In valve industry, here are always common issues to resolve. For example, the absurd design, negligent manufacture, failure material selection, relaxed assemble, inattentive maintenance and so on. All of these would be a result of damage seal surface of the valve.

Furthermore, the breakdown under the conditions of normal operation, it is hardly avoided etching and washout from media to seal surface.

It takes the gate valve not according to the load prerequisites. Either the way of closing is too quick or it is too tight. The improper heat treatment, the hardness of seal surface is too high or too low, all of these is no capable to resistance to erosion.

Beyond that, the mechanical injury is the main factor. In the begin of the stroking, it is intend to gauge and bump, due to the influence of high temperature and pressure, the molecules would be an infiltration and exosmosis each other that causes the stick phenomenon.

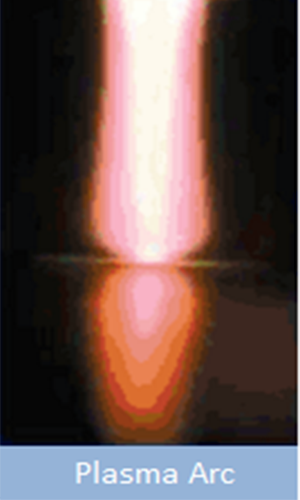

We always to use the way of reproducing to repair steel valve. The surfacing materials for valve are cobalt-based alloys, nickel-based alloys, iron-based alloys and copper-based alloys, which made into electrode, welding wire (including flux-cored wire), flux (including transition alloy type flux) and alloy powder, etc., using manual arc welding, oxyacetylene flame welding, tungsten argon welding, submerged arc automatic welding. Here we introduce the cladding process of PTA welding.

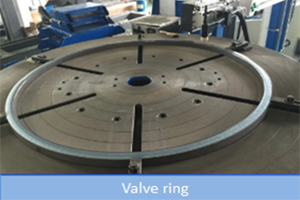

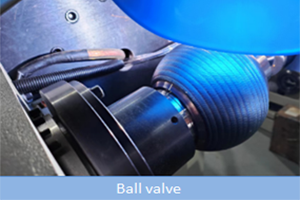

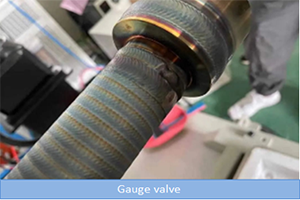

The application cases in valve as follows,

Video

Post time: Nov-02-2022