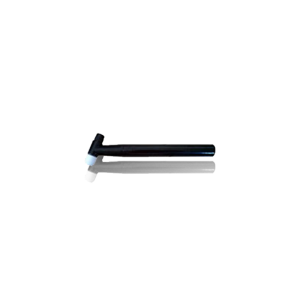

HRWS Precision Repair Welding Machine

Product Advantages

• Small heat-affected zone (HAZ).

• No deformation, no edge collapse, no pores, and no sand holes.

• High precision and accuracy — capable of welding any fine geometric area; the thinnest welding wire available is 0.1–0.2 mm.

• Easy and flexible to use; on-site repair is possible, eliminating the need for costly disassembly of workpieces or repair sections.

• Applicable for repairing cracks, chipping, edges, blowholes, and wear damage. It can also be used for re-welding workpieces after EDM, nitriding, or soft nitriding treatment.

• Strong bonding strength; suitable for various machining processes without issues such as poor adhesion or peeling.

• Capable of efficient, low-temperature precision repair welding over large areas.

• By using materials of different hardness, various post-weld hardness levels (e.g., up to HRC 60°) can be achieved.

Product Parameter

Product application