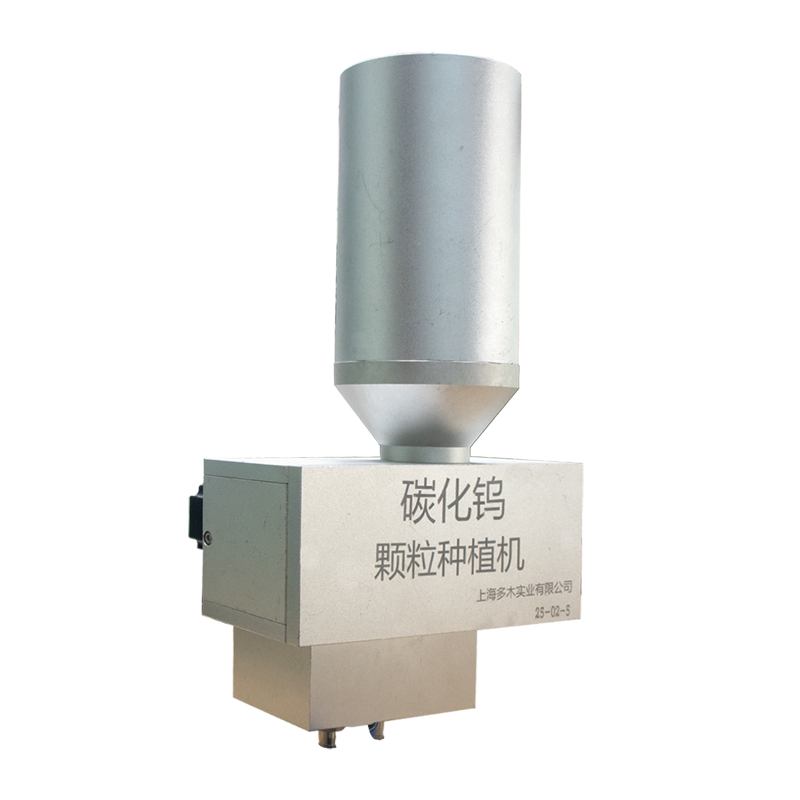

Powder feeder for PTAW & Laser Cladding

Powder feeder structure

The storage tank is used to store powder, transparent and convenient for observing the powder condition.

There is a rotating nut at the powder feeding port, which can be manually tightened to remove the nut and add powder from here.

Install a stepper motor at the powder unloading point to control the precise powder feeding during the working process. There is an on/off valve at the powder unloading port, which can be used to pour the remaining powder and reuse it.

The observation window is set to be transparent, which can observe the direction of motor rotation and the remaining amount of powder. It can also be used to check whether the powder feeding device is normal.

Parameters of the powder feeder

Add a control valve and powder feeding tank on top of the original powder feeding system, which can continuously add powder to the upper tank during operation to achieve uninterrupted machine operation.

| Powder feeding amount (g/min) | 3-50 | 5-120 |

| Powder feeding motor | Stepper motor | Stepper motor |

| Powder feeding accuracy (%) | ≤5 | ≤5 |

| Powder storage filling capacity (kg) | 10 | 10 |

| Adapt to powder particle size (mesh) | 80-300 | 80-300 |

| Powder feeding air flow(m3/h) | 0.2-3 | 0.2-4 |

| Powder feeding pressure limit (MPa) | ≤0.4 | ≤0.4 |

| Powder feeding amount (g/min) | 3-50 | 5-120 |

The particle size of welding powder is not easy to be too large or too small, and it is advisable to use 80-200 mesh.

The powder sent out with too small particles is easy to blow away, leading to a decrease in the utilization rate of the powder.

Excessive particle size can easily cause blockage in the powder feeding channel of the welding gun, leading to the scrapping of the welding gun.

Before adding welding powder, it is necessary to filter with the provided sieve to avoid the above phenomenon.

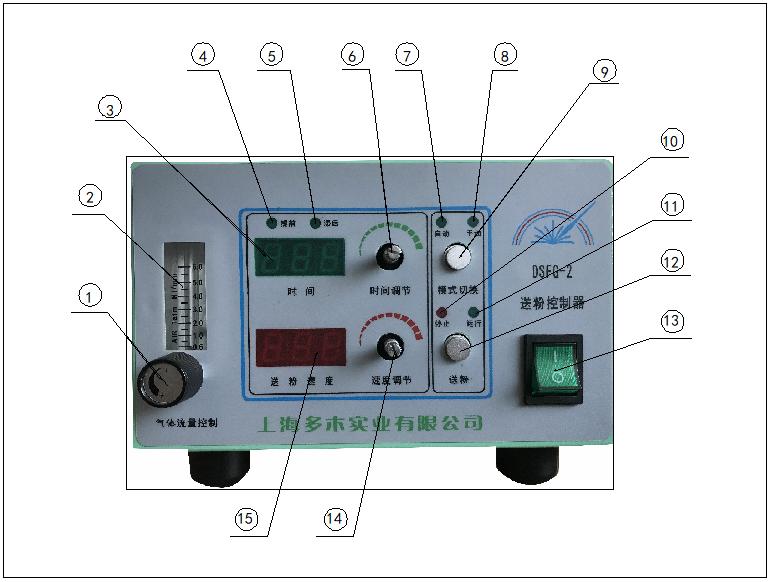

Powder feeding control box function

The storage tank is used to store powder, transparent and convenient for observing the powder condition.

There is a rotating nut at the powder feeding port, which can be manually tightened to remove the nut and add powder from here.

Install a stepper motor at the powder unloading point to control the precise powder feeding during the working process. There is an on/off valve at the powder unloading port, which can be used to pour the remaining powder and reuse it.

The observation window is set to be transparent, which can observe the direction of motor rotation and the remaining amount of powder. It can also be used to check whether the powder feeding device is normal.

1、Protective gas flow meter adjustment knob

2、Flow indication of protective gas flow meter

3、Display window for early/delayed powder feeding time

4. Early powder feeding indicator light.

5.Delayed powder feeding indicator light.

6. Adjustment knob for early/delayed powder feeding time.

7. Automatic powder feeding indicator light.

8.Manual powder feeding indicator light.

9. Automatic/manual switch selection button.

10. Stop running indicator light

11. Working status indicator light

12. Start button

13. Power switch

14. Power input 16, foot switch interface

15. Welding machine linkage control interface

16, motor output interface

17. Powder gas outlet interface

18. Powder gas inlet interface

| Main technical parameter model | DSFG-2 | |

| Manual feeding | Automatic powder feeding | |

| Powder feeding speed (r) | 0-100 | 0-100 |

| Powder feeding time in advance (s) | 0 | 0-5 |

| Lag powder feeding time (s) | 0 | 0-5 |

| Input voltage (V) | 220V, 50HZ AC | |

| Weight(KG) | 3.5 | |

| Dimensions (mm) | 270*220*155 | |

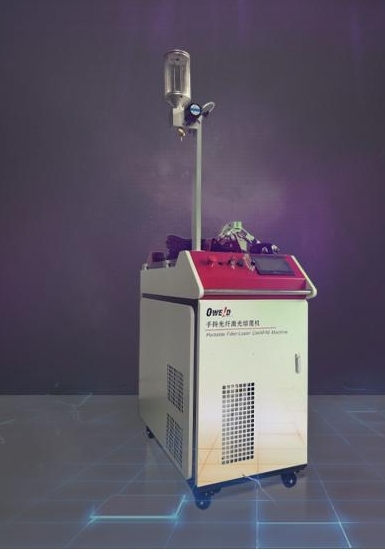

Plasma welding machine

Application of powder feeder

The storage tank is used to store powder, transparent and convenient for observing the powder condition.

There is a rotating nut at the powder feeding port, which can be manually tightened to remove the nut and add powder from here.

Install a stepper motor at the powder unloading point to control the precise powder feeding during the working process. There is an on/off valve at the powder unloading port, which can be used to pour the remaining powder and reuse it.

The observation window is set to be transparent, which can observe the direction of motor rotation and the remaining amount of powder. It can also be used to check whether the powder feeding device is normal.

Plasma welding machine

Laser cladding machine

Other types of powder cladding process equipment