Brick reamer is an important tool in brick production line, its role is to cut the raw material into the required shape and size. Due to the long time use of brick machine reamer, the wear and corrosion of reamer will affect the productivity and quality of brick machine. Therefore, the brick machine reamer wear-resistant surfacing has become an important means to improve its service life and productivity. In this paper, we will introduce the knowledge, problem description and solution of wear-resistant surfacing of brick machine reamer, and compare it with other solutions through the actual application effect to summarize the superiority and application prospect of this solution.

Background Knowledge:

The brick machine reamer consists of a cutter body, a cutter head and a shank. The cutter body is made of high-speed steel, while the cutter head and handle are made of cast iron or steel. The working principle of the reamer is to utilize the high-speed rotating cutter head to cut the raw material into the desired shape and size. In the process of use, the reamer will be affected by factors such as high temperature, high pressure and corrosion, resulting in increased wear and corrosion. Therefore, wear-resistant surfacing of brick machine reamer becomes an important means to improve its service life and productivity.

Problem elaboration:

The main problems of brick machine reamers in the process of use are as follows:

The cutter head and shank of the reamer appear phenomena such as fracture and deformation;

Corrosion on the surface of the cutter head and shank of the reamer, affecting its precision and cutting quality;

The reamer is prone to vibration in use, which reduces cutting precision and quality;

The reamer will have obvious vibration and trembling phenomenon in long time use.

Solution:

The following solutions are proposed for the above problems:

Replacement of reamers: reamers with phenomena such as breakage and deformation need to be replaced. Select high-quality reamer material and manufacturing process to ensure its service life and cutting quality;

Improve the design: For the problem of corrosion on the surface of reamers, the surface of the reamer can be chromium-plated or coated with anti-corrosion materials to improve its corrosion resistance;

Reduce vibration: for the reamer in use easy to produce vibration problems, you can reamer for fine processing, reduce the vibration of the cutting process, improve cutting accuracy and quality;

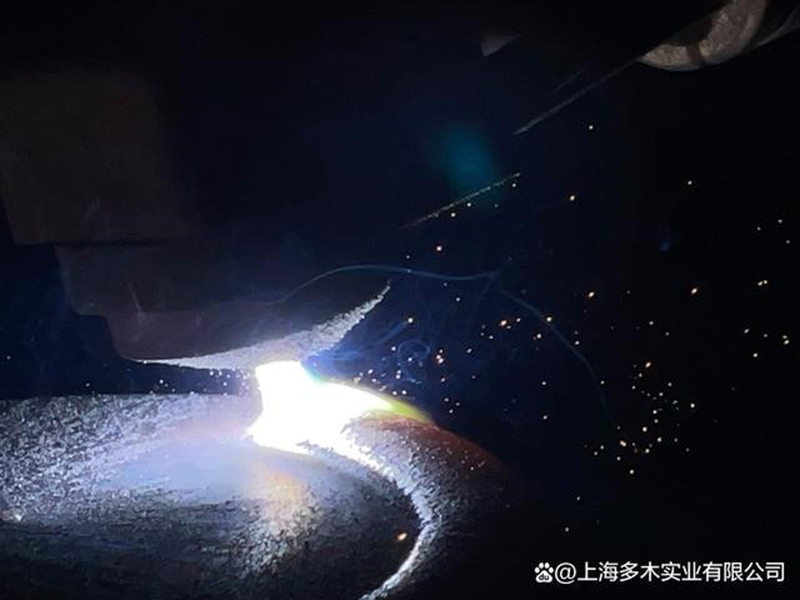

Enhance wear resistance: for long time use of obvious vibration and shaking phenomenon, can be in the reamer base material to add some wear-resistant materials, enhance its wear resistance.

Practical applications:

The solution has been proven in practical applications. By replacing high-quality reamer materials and manufacturing processes, and treating the reamer surface with treatments such as chromium plating or coating with anti-corrosion materials, its corrosion resistance has been improved and its service life extended. At the same time, cutting accuracy and quality have been significantly improved through measures such as fine machining and vibration reduction. Compared with other solutions, this solution has better corrosion resistance, higher cutting precision and quality, and longer service life.

Post time: Oct-12-2023