Pulse Patch Welding Technology: A Key Method to Achieve Efficient Welding and Material Optimization

With the rapid development of modern manufacturing industry, welding technology is increasingly widely used in various engineering fields, and welding quality and efficiency play a pivotal role in the performance and reliability of products. Among many welding technologies, pulse refill welding, as an advanced welding method, has gradually become a popular welding technology in the manufacturing industry by virtue of its high efficiency, low cost and environmental protection.

●First, pulse welding technology introduction

Pulse refill welding is a periodic pulse current arc welding technology, through the adjustment of pulse parameters, to achieve precise control of the weld pool, so as to optimize the welding process of heat input, melt depth, melt width and other key parameters, to improve the quality of the weld and welding efficiency. Pulse filler welding technology can be widely used in carbon steel, stainless steel, aluminum alloy and other metal materials welding.

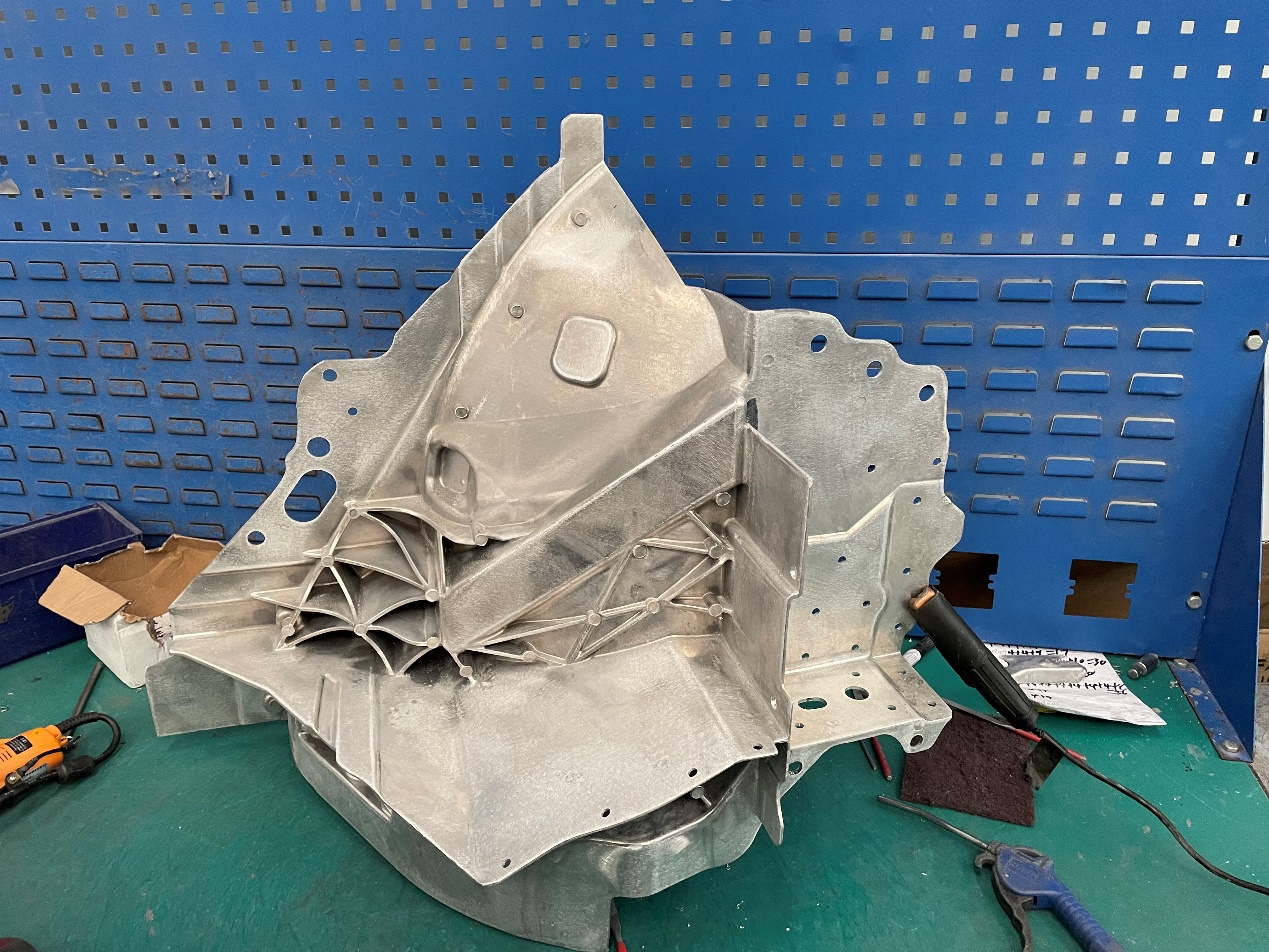

Welding of automotive thin-walled parts with missing corners

Welding of automotive thin-walled parts with missing corners

Before repair

Welding of automotive thin-walled parts with missing corners

After refill welding

Welding of automotive thin-walled parts with missing corners

After sanding and refinishing

●Second, the advantages of pulse repair welding technology

1. Efficient welding

Pulse filler welding technology through precise control of pulse current, real-time monitoring and adjustment of the weld pool in the welding process, to avoid overheating, burn-through and other problems in the traditional welding methods, thus improving the welding speed and efficiency.

2. Material optimization

By adjusting the pulse parameters, pulse filler welding technology can realize precise control of the melt depth and melt width of the melt pool, so that the weld forms a uniform and dense structure, and improves the tensile strength, impact resistance and corrosion resistance of the weld, thus optimizing the performance of the welding material.

3. Energy saving and environmental protection

Pulse filler welding technology has a low heat input and high energy utilization, compared with traditional welding methods, can significantly reduce energy consumption, reduce the harmful gases and fumes produced in the welding process, improve the safety of the production environment and environmental protection.

4. Strong adaptability

Pulse filler welding technology is suitable for welding a variety of metal materials, whether it is thin or thick plate, whether it is flat welding, horizontal welding or vertical welding, can realize high-quality welding effect, to meet the diversified needs of the project.

●Third, the pulse welding technology in the practical application of the case

Pulse filler welding technology in a variety of engineering fields in the increasingly wide range of applications, such as automobile manufacturing, shipbuilding, aerospace, petrochemical and other industries. The following are some typical application cases:

1. automobile manufacturing: pulse filler welding technology has been widely used in the welding of automobile body, chassis, exhaust system and other components, which effectively improves the quality of weld seam and production efficiency, and reduces the cost.

2. Shipbuilding: pulse filler welding technology plays an important role in the welding of hull structures, ship equipment, piping systems and other key components in the shipbuilding process, which improves the strength and corrosion resistance of the ship structure and prolongs the service life of the ship.

3. aerospace: in the aerospace field, pulse filler welding technology is used in a variety of high-strength, lightweight material welding, such as aluminum alloys, titanium alloys, etc., to ensure that the weld is of high quality and high reliability, to meet the aviation and spacecraft for the lightweight and high-performance requirements.

4. Petrochemical industry: pulse welding technology in the petrochemical industry, pipelines, tanks, heat exchangers and other equipment manufacturing and maintenance has played an important role in improving the quality of welding, reducing maintenance costs, to ensure production safety.

●Fourth, the development prospects of pulse welding technology

With the continuous progress of engineering technology, people's welding quality and efficiency requirements are increasingly high. Pulse welding technology with its significant advantages, has become an important trend in the development of welding technology.

In the future, pulse welding technology will make more breakthroughs in the following aspects of development:

automation and intelligence: combined with modern control technology and artificial intelligence technology, to further improve the automation and intelligence of the pulse welding process, realizing real-time monitoring and adaptive adjustment of the welding process to improve welding quality and efficiency.

2. new material welding: with the continuous emergence of new metal materials and composite materials, pulse welding technology will make important breakthroughs in the welding of new materials to meet the efficient demand for new material welding in various fields.

3. green welding: in the context of energy saving and environmental protection, pulse welding technology will continue to optimize the use of energy and reduce the harmful substances produced in the welding process, to achieve the greening of the welding process and sustainable development.

In short, pulse refill welding technology as a high-efficiency, low-cost and environmentally friendly welding methods, in the modern manufacturing industry has a broad application prospects. With the continuous innovation and development of related technologies, pulse welding technology will play a more important role in the welding field, providing strong support for the engineering construction and scientific and technological progress of human society.

●Related Product Links

Website:https://www.ourcladding.com/all-digital-intelligent-precision-replacement-welding-equipment-hrws-3160-product/

Website:https://www.ourcladding.com/high-integration-integrated-plasma-powder-welding-machine-dml-v03bd-product/

Youtube: https://www.youtube.com/watch?v=b0YygZcUIpw&t=13s

Tiktok: https://www.tiktok.com/@duomushanghai/video/7347496185868848392

Post time: Apr-16-2024