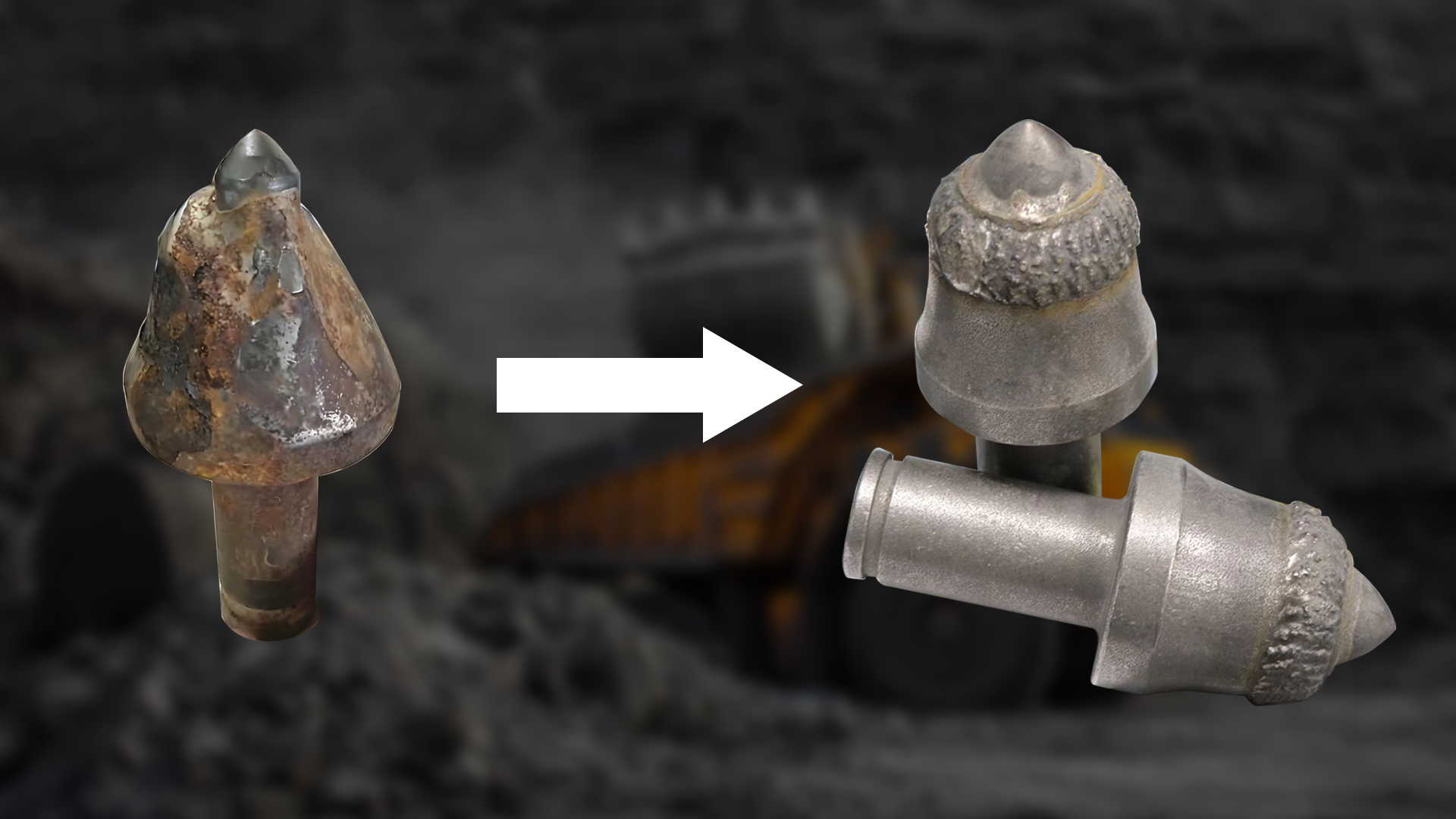

In mining and tunneling operations, cutting picks are among the most critical wear-prone components. Due to prolonged exposure to harsh conditions involving high impact, high friction, and high corrosion, traditional cutting picks often suffer from rapid wear, short service life, and frequent replacement, resulting in persistently high downtime maintenance costs.The application of PTA-PST technology offers a new solution for surface strengthening of cutting picks.

What is PTA-PST technology?

Plasma Transferred Arc (PTA) technology, combined with the innovative Postposition Surfacing Welding Tungsten Carbide (PST) process, forms the “Plasma Coaxial Postposition Surfacing Welding Tungsten Carbide” solution.

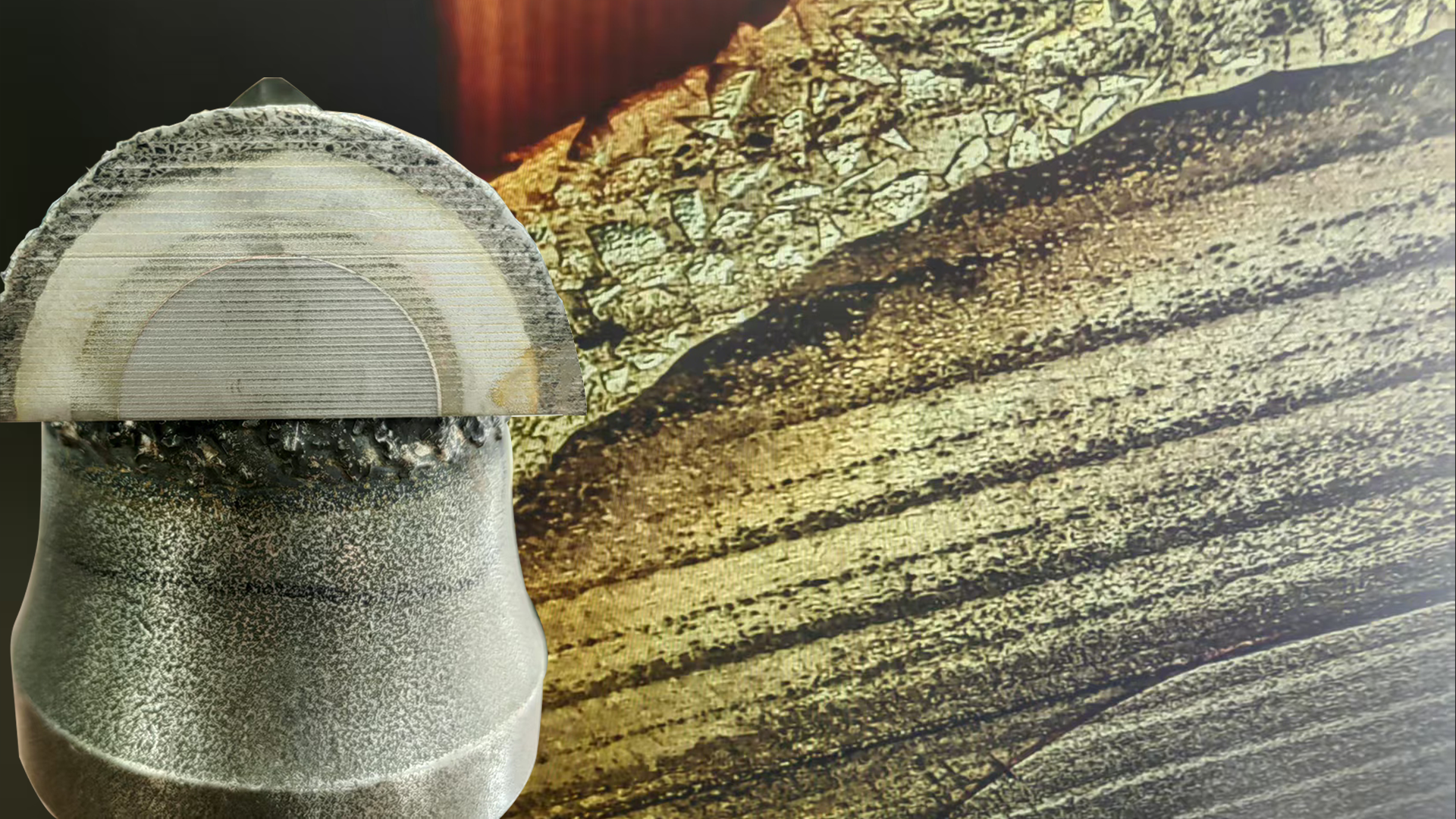

This process utilizes the plasma arc as a heat source to precisely feed tungsten carbide particles into the welding zone. The particles rapidly melt and firmly bond to the substrate surface, forming a dense, pore-free, crack-free wear-resistant protective layer.

Advantages of PTA-PST Technology

1. Superior wear resistance

- The hardness of tungsten carbide can reach over HV1800, together with the dense organization of plasma welding, the life span of the parts in the environment of strong abrasion and impact can be increased by 3-5 times.

2. High bonding strength

- Adopting coaxial post-feeding method, the tungsten carbide particles are evenly distributed in the molten pool, which makes the metallurgical bond stronger and avoids the problems of spalling and cracking in the traditional process.

3. Highly controllable process

- By precisely controlling the plasma energy and powder feeding rate, it is possible to realize consistent layer thickness, uniform organization and smooth surface of the welding layer.

Which parts are suitable for PTA-PST technology?

• Drill bits, drilling tools, etc. Oil and gas energy equipment

• Rolls, crushers, bucket teeth, etc. Mining and metallurgical machinery

• Valves, pumps, valve seats, etc. Fluid control components

• Aircraft landing gear, engine parts, etc. Aerospace structural parts

FAQ about PTA-PST Technology

Q1. Why choose PTA-PST technology?

- PTA-PST technology can form a high hardness, dense and strong bonded tungsten carbide wear-resistant layer on the surface of the workpiece, which greatly improves the service life of the parts under high wear conditions, especially suitable for demanding industries such as oil drilling, mining, metallurgical rolling and aerospace.

Q2. What are the advantages of PTA-PST process compared with traditional welding process?

- Traditional welding: prone to cracks, porosity and spalling, with limited life span.

- PTA-PST Surfacing: plasma coaxial powder feeding, uniform distribution of the molten pool, dense weld layer organization, higher bonding strength, life expectancy increased by 3-5 times.

Q3. Can I control the thickness of PTA-PST tungsten carbide welding layer?

- Yes, it is possible. By adjusting the plasma energy and powder feeding rate, the thickness of the weld layer can be controlled flexibly from a minimum of 1.5mm to meet the wear-resistant requirements of different working conditions.

PTA-PST (Plasma Coaxial Postposition Surfacing Welding Tungsten Carbide) technology breaks through the bottleneck of traditional welding technology and realizes the solution of high-efficiency, high-quality and low-energy consumption welding.

For more information about Plasma Coaxial Postposition Surfacing Welding Tungsten Carbide (PTA-PST)technology, or to discuss your specific repair needs, feel free to email us! Our team of experts is ready to provide customized solutions for your specific application.

Post time: Aug-27-2025