This technology significantly improves valve performance and durability in extreme environments. By enhancing the sealing surface of the valve, this technology sets a new industry standard in improving overall equipment reliability and efficiency.

Technology Overview

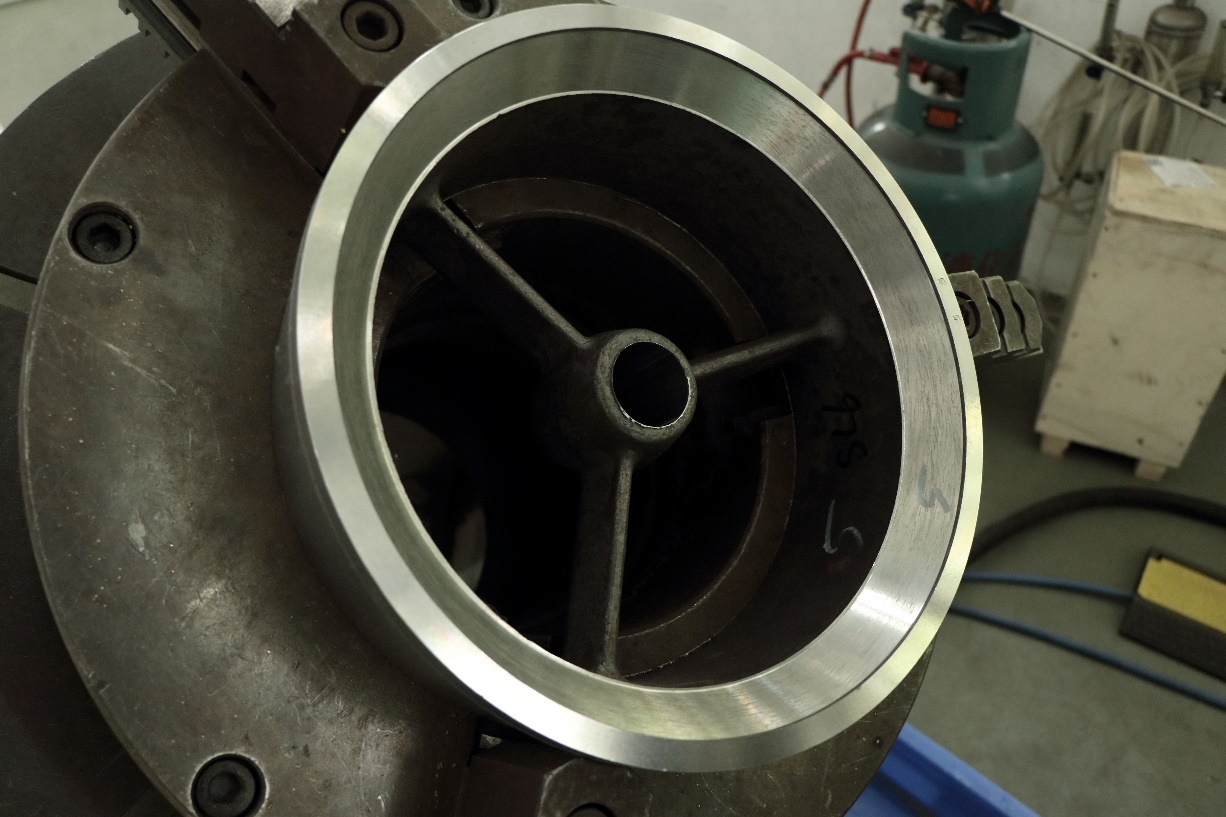

Plasma cladding technology utilizes a high-energy plasma arc as a heat source to melt and build up Stellite alloy powder onto the sealing surface of the valve. The process takes place in a specially controlled environment to ensure coating uniformity and adhesion. Through fine control of the buildup parameters, such as current, voltage, powder feed rate and protective atmosphere, the technician is able to precisely manipulate the microstructure of the coating to achieve optimum physical and chemical properties.

Technical Advantages

Excellent corrosion resistance: The Stellite alloy layer provides an effective barrier to corrosive media, preventing them from attacking the base metal of the valve, especially when handling fluids containing sulfide, acidic or alkaline chemicals.

Enhanced wear resistance: The high hardness of the coating ensures that the durability of the valve is greatly enhanced when used in sandy water streams or other abrasive fluids.

Improved mechanical strength and toughness: the plasma cladding technology allows for a very strong bond between the Stellite alloy and the base material, increasing the stability of the valve’s performance in high-pressure environments.

Adaptability: The technology can be adapted and optimized for different operating conditions and valve materials, ensuring that it delivers the best possible performance in a wide range of operating environments.

Economic benefits: Despite the high initial investment, the overall cost benefits are significant in the long term due to reduced maintenance requirements and extended equipment life.

Application Prospects

This technology of valve sealing surfaces enhanced by plasma cladding of Stellite alloys is beginning to see widespread use in oil and gas refining, chemical processing and other industrial applications requiring high durability. It is expected that as the technology matures and is optimized, its application areas will be further expanded to more high-risk environments such as offshore mining, nuclear energy, and high-temperature and high-pressure scenarios.

Conclusion

The successful application of Stellite alloy plasma cladding technology has brought unprecedented technological progress to the valve manufacturing industry, heralding the prospect of wider industrial applications and market potential. With the further development of the technology, it is expected to provide a continuous driving force for the reliability and efficiency of industrial equipment.

Post time: Apr-28-2024