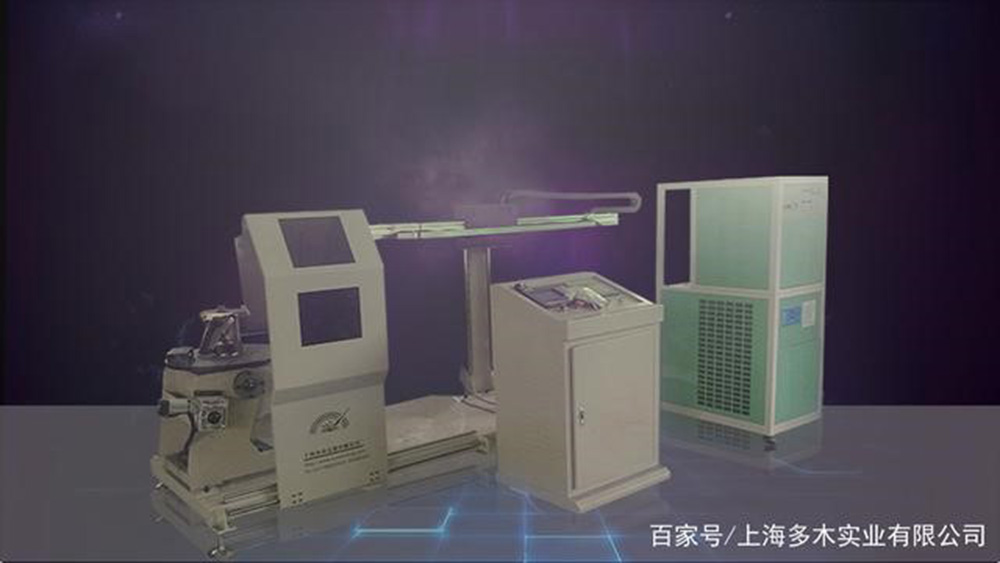

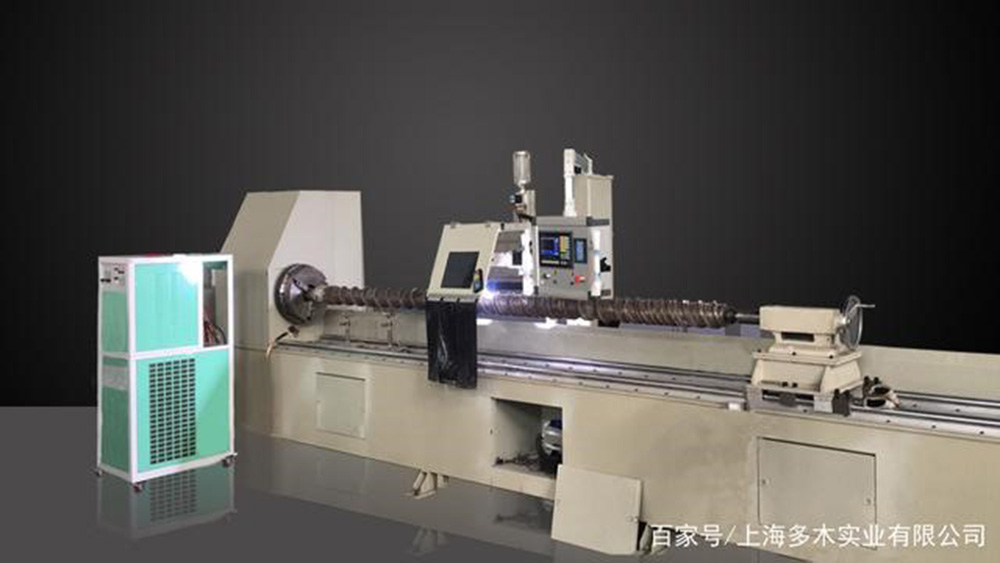

Plasma Transfer Arc Welding (PTA Welding) is a heat treatment process that applies a wear and corrosion resistant layer to the surface of a metallic material. A high-energy plasma arc melts the surface of the base material. At the same time, a powdered filler material is inserted into the arc and melts. During the curing process, a substance-to-substance bond is formed between the filler material and the base material.

Advantages of PTAW Surfacing:

Can be highly automated - easy to replicate

Small heat affected zone - no metal warpage

High powder utilization

Low dilution rate

Very wide range of surfacing materials

Range of PTA:

Chutes, liners;

Wear plates in dump truck bodies;

Wear plates in excavator and pulling shovel buckets;

Wear strips 6 on 10, 3 on 10 etc.

Guards - lips, heels, wings;

CHPP wear liner packages;

Shaft assemblies for rotating equipment devices, shafts and housings;

Pump casings;

Valves;

Crushing equipment;

Industrial fans;

What is the cost of PTA Hardfacing?

All prices offered are based on customized wear patterns and powder selection. As a guide, we aim for around $7 per square inch. It is important to understand that cost and value are two very different things. When you use PTA hardafcing, the upfront cost is higher, but the savings are significant due to fewer changeovers and machine downtime and the need to reorder as many parts as possible. In some environments it is not unheard of to have a life expectancy of more than 3x and sometimes as high as 7x when using wear plates. The question maintenance personnel should be asking themselves is, how much does it cost to shut down my machine while the GET is being replaced? The answer is always far more than paying extra for case-hardened parts.

Plasma Surface Hardened Edges

Plasma Surface Hardening has access to an international supplier of a wide range of high quality, specialist powders to provide a greater range of innovative wear solutions for all environments. Research and development is at the heart of everything we do, aiming to develop Plasma branded powders that are unique to our customers and can be tailored to deliver outstanding results for their unique wear environments.

Our team has the experience and attitude to provide an excellent service, giving you the peace of mind that your parts are in safe hands. It will not leave the workshop unless it meets our strict quality control standards.

For many mines the technology has been successfully trialled but the cost is too high.Plasma Hard faces recognizes that in this difficult financial climate customers need value for money and an improved cost benefit ratio. We deliver the same great results at the right price to maximize your profits.

Post time: Sep-25-2023