Gears, as key transmission components in industrial equipment, are prone to wear, cracks, spalling and other problems in long-term operation. Traditional repair methods often have defects such as large deformation and short life. Laser cladding repair gear technology is becoming an important solution in the field of gear remanufacturing due to its advantages of high efficiency, precision and high life.

Before we look at laser repair of gears, let's first understand “What is laser cladding?”

What is laser cladding technology?

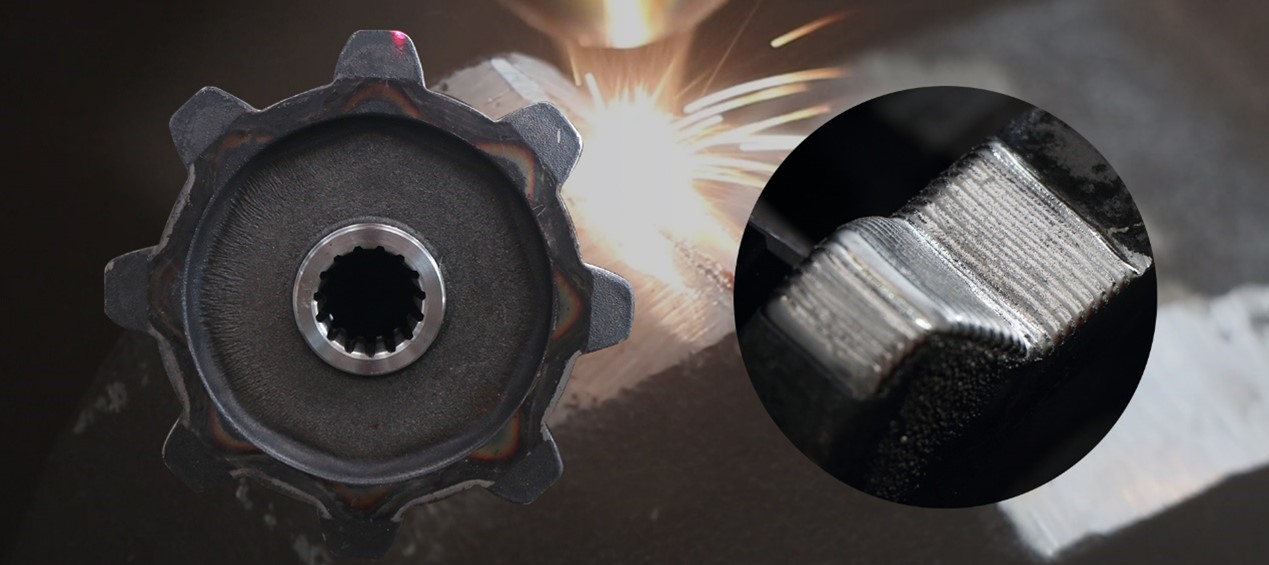

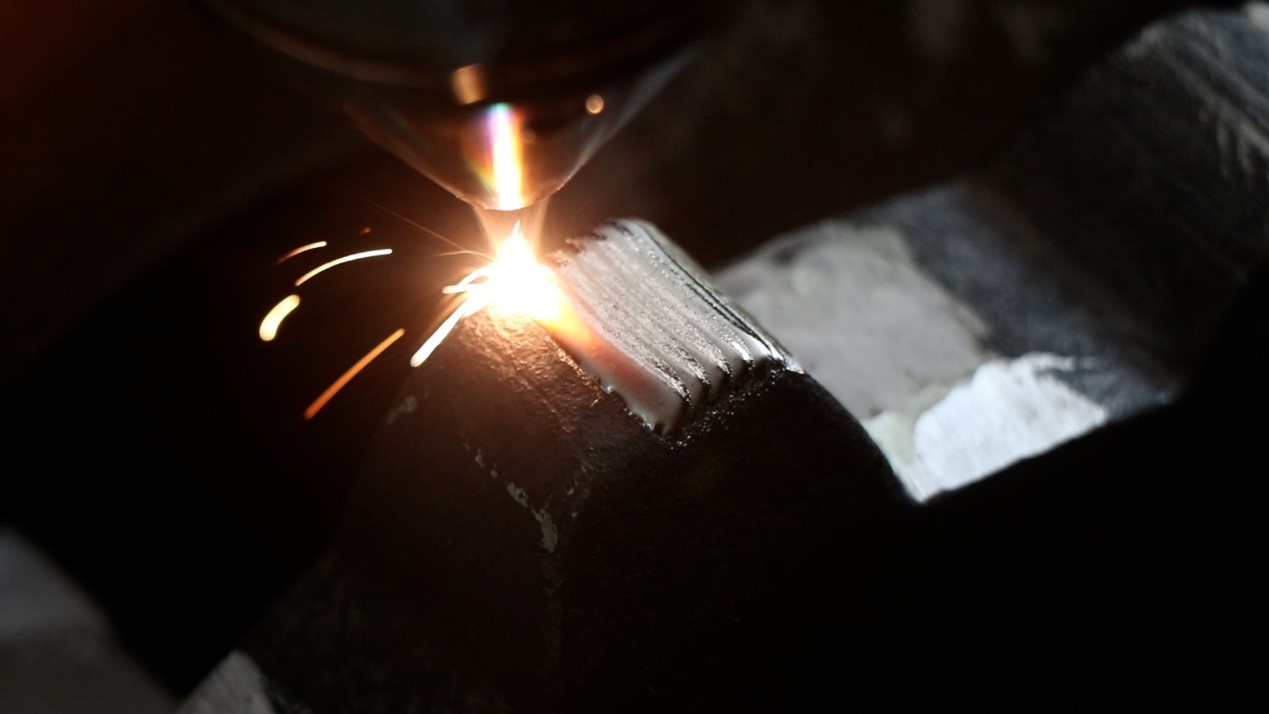

Laser cladding is a surface modification technology that uses a high-energy laser as a heat source to melt metal alloy powder onto the surface of gears. Compared with the traditional welding and cladding repair methods, laser cladding realizes metallurgical bonding with the base material, dense cladding layer, low dilution rate, and very small heat affected zone.

In gear repair applications, laser cladding is able to accurately restore the shape of the gear teeth, and at the same time improve its surface hardness and wear resistance, thus extending the overall service life of the gear.

What gear damage is laser cladding used for?

Laser cladding is particularly suitable for repairing the following types of gear damage:

• Tooth wear

• Pitting and fatigue spalling

• Cracks or microfractures in gears

• Thermal deformations or occlusion marks

• Localized corrosion and pits

Whether transmission gears for heavy-duty equipment or high-precision gears for precision machinery, as long as there is no serious structural damage to the gear body, they can be effectively repaired by laser cladding.

The process of laser cladding repair of gears

Laser cladding repair of gears typically involves the following key steps:

1.Gear surface preparation

Pre-treatments such as cleaning, grinding and degreasing remove surface impurities and enhance the adhesion of the fused cladding.

2. Selection of cladding materials

According to the working conditions and materials of gears, select the appropriate alloy powder, for example:

- Iron-based alloys (commonly used in ordinary carbon steel gears)

- Nickel-based alloys (used for high corrosion resistance and high hardness requirements)

- Cobalt-based alloys (suitable for high temperature working conditions)

3. Laser cladding operations

Localized cladding on the tooth surface is carried out by laser equipment with precise control of spot, scanning path and layer thickness to ensure uniform cladding.

4. Post-treatment and finishing

• Heat treatment (e.g. tempering) to eliminate internal stresses;

• Precision grinding or milling to restore tooth shape accuracy and surface roughness;

• Hardness, dimensional and metallurgical testing to ensure that the quality is up to standard.

Advantages of laser cladding gear repair

Compared with traditional cladding or refinishing welding, laser cladding is superior in many aspects. The cladding layer is metallurgically bonded to the substrate, which has high bonding strength and is not easily dislodged, whereas the traditional process is mostly mechanically bonded, which is less robust. The hardness of the tooth surface after laser cladding can reach HRC55-65, which is much higher than HRC40-50 of traditional repair.

In addition, the heat-affected zone of laser cladding is less than 1mm, which avoids the problem of gear deformation, and the repair accuracy can reach micron level, which is suitable for high-precision parts. It can also flexibly use a variety of alloy powders to adapt to different working conditions. In terms of service life, the gears repaired by laser cladding can often be close to or exceed the new parts, while the traditional method is obviously inferior.

Laser cladding enables gears to achieve the effect of “repair is upgrade”, not only to restore the size, but also to improve its wear and fatigue resistance.

Industry Application Case

Case 1: Wind Turbine Main Shaft Gear Repair

In wind power equipment, the main drive gear pitting and wear due to long time heavy load operation. After laser cladding with nickel-based alloy, the hardness of the tooth surface is increased to HRC58, which extends the service life to at least 3 years and avoids the high cost of replacing the whole set of gear components.

Case 2: Engineering machinery transmission gear repair

Engineering vehicles are frequently used, and gears often have spalling and tooth damage. After repairing with iron-based alloy laser cladding, the precision of tooth shape is restored to ±10μm, and the strength of tooth surface is increased by more than 20%.

Case 3: Aviation high-precision gear remanufacturing

The gears of an aviation component are slightly cracked and bitten, through laser cladding + precision grinding process, 100% size recovery is realized, and the flight safety standard is reached.

Frequently Asked Questions (FAQ)

Q1: How long is the service life of the repaired gears after laser cladding?

Depending on the cladding material and the usage environment, the service life of repaired gears can be up to 80%-120% of the new parts.

Q2: Can gears be re-processed after laser repair?

Yes. The cladding layer can be routinely ground, milled and heat-treated to meet secondary processing and assembly requirements.

Q3: Can all gears be repaired by laser cladding?

No, it is not. Laser cladding is not recommended if the gear root is fractured or the substrate is severely deformed. However, it is effective for repairing most of the damages caused by wear and occlusion.

Conclusion

Laser cladding repair gear technology is gradually replacing the traditional repair process, becoming an important means of remanufacturing high-value mechanical components. Its high strength, precision and environmental characteristics are particularly suitable for wind power, construction machinery, rail transportation, aerospace and other industries.

If you are looking for an efficient, low-cost, high-quality gear repair solution, laser cladding is undoubtedly a priority choice. Please contact our technical team for technical inquiries, quotes, or to learn more about the application of your equipment, and we will provide you with one-on-one professional support.

Post time: Jul-12-2025