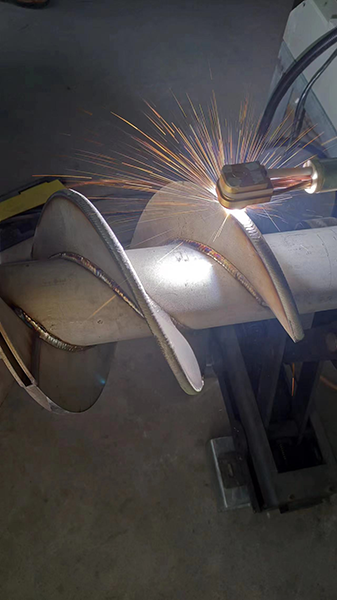

The case of PTA welding spiral shaft of ad-hoc machine for horizontal

A new model of PTA welding machine has been developed that is specifically designed for spiral shafts. This versatile machine is not only capable of welding horizontally, but also vertically. It is a smart and versatile tool that can be customized according to the distance between spirals. If the spaces are small, the low current torch is available, while the high current torch is used for larger spaces.

The plasma torch used for inner PTA welding is highly efficient and reaches the welding location without any hassle. This makes it an ideal choice for spiral shafts that require precision welding.

The outer edge surface of the spiral shaft can be welded using either horizontal or vertical tooling, as both are valid options. However, when welding the pressure side of the blade, vertical tooling is more adaptive.

One of the most remarkable features of this PTA welding machine is that it does not require preheating or post-welding solutions. The welding process involves fixing the workpiece, setting the parameters, starting the programming, and then removing the workpiece from the fixture after welding. This saves both human and material resources, making the welding process highly efficient and cost-effective.

Overall, this PTA welding machine is an innovative and highly effective tool that has revolutionized the welding process for spiral shafts. Its smart and versatile design makes it an ideal choice for a wide range of welding applications.

The new PTA welding machine for spiral shafts has already made waves in the welding industry, offering a solution for precise and efficient welding of spiral shafts. This machine is capable of welding in both horizontal and vertical orientations, and the customer can choose the appropriate torch depending on the distance between spirals.

The plasma torch used for inner PTA welding is a unique feature of this machine, allowing for precise and accurate welding without any issues. It can easily reach the welding location without any obstructions, making it an ideal choice for spiral shafts that require precision welding.

When it comes to welding the outer edge surface of the spiral shaft, both horizontal and vertical tooling options are valid. However, when welding the pressure side of the blade, vertical tooling is more adaptive. This shows the versatility of this machine, which can handle a variety of welding situations with ease.

Moreover, the PTA welding process does not require preheating or post-welding solutions, making it an incredibly efficient and cost-effective option. The process involves fixing the workpiece, setting the parameters, starting the programming, and removing the workpiece from the fixture after welding. This not only saves time but also reduces the overall cost of the welding process.

Video

Post time: Nov-05-2022