Comparative advantages and disadvantages of traditional techniques

In today’s rapidly developing field of materials science and surface engineering, plasma cladding process has attracted a lot of attention due to its unique advantages. But what makes plasma cladding different? Why has it become the technology of choice for so many industries? This article explores the advantages and disadvantages of plasma cladding and the technological innovations behind it by comparing it to conventional processes.

Traditional Comparison

First of all, compared to traditional surface treatment technologies such as flame spraying and arc spraying, plasma cladding shows its obvious advantages in terms of efficiency, precision and environmental protection. Plasma cladding utilizes the high temperature characteristics of plasma to efficiently complete the melting and solidification of materials in a short period of time, thus improving production efficiency and reducing energy consumption.

Secondly, plasma cladding process can realize higher material utilization and better cladding quality. Compared with traditional processes, plasma cladding can reduce the waste of materials, and through the precise control of process parameters, the preparation of cladding with better density, stronger bonding force and better performance, which significantly improves the wear resistance, corrosion resistance and high temperature resistance of products.

Opportunities and challenges

However, the application of plasma cladding is not without challenges. Compared with traditional methods, the equipment cost and technical requirements are high, and specialized operators are needed for management and maintenance. In addition, the applicability and economy of the plasma cladding process for some specific materials or special application scenarios still need to be further studied and optimized.

Despite these challenges, plasma cladding has become an indispensable technology for many key industries such as aerospace, automotive, energy, medical and others due to its significant advantages in material treatment. It not only represents an important development direction for surface engineering technology, but also an important force for innovation in materials science and industrial applications.

Looking ahead, with the deepening of research and development and the maturity of technology, plasma cladding process is expected to show its value in a wider range of fields, opening up a new path for realizing a more efficient, environmentally friendly and sustainable production mode.

Plasma Cladding Video

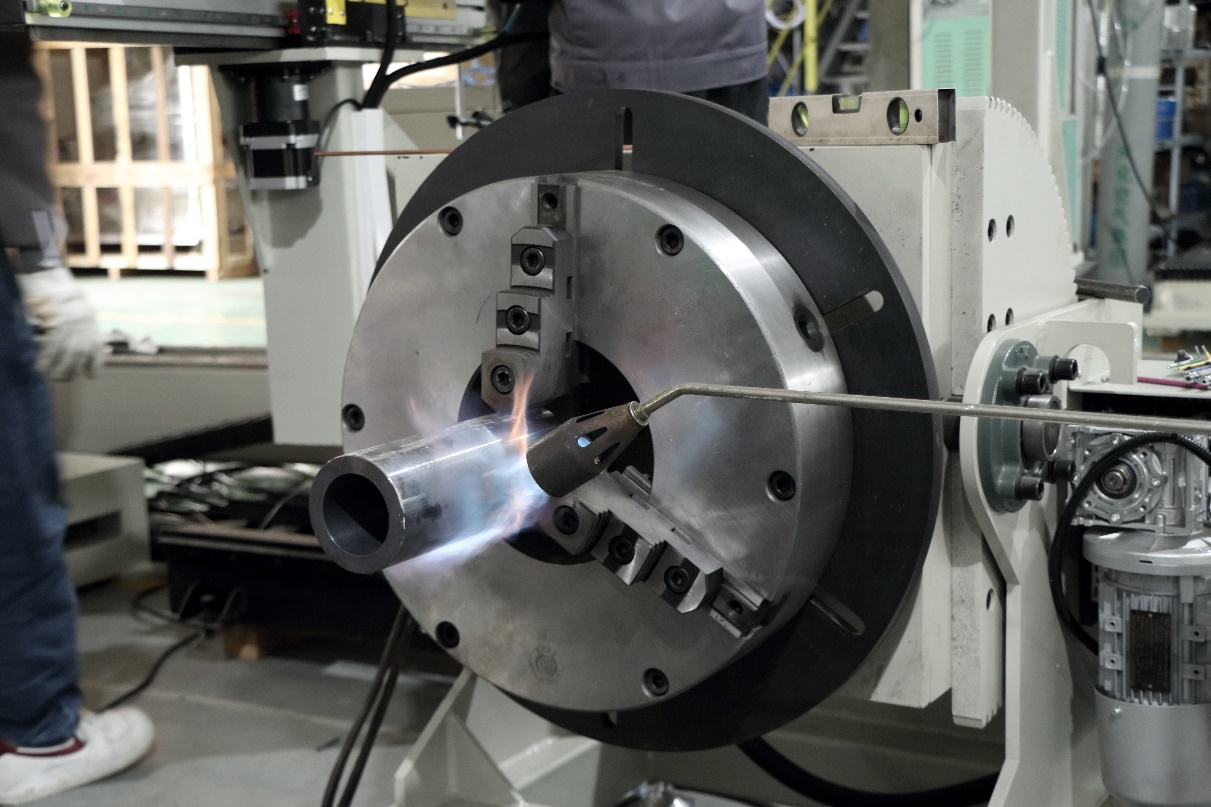

Surface cladding of bushings

Surface cladding of valve seats

Bore cladding for TC bearings

Post time: Apr-28-2024