1. Equipment Manufacturing: High Precision and High Reliability Ensure Quality Assurance

As a high-tech enterprise, Shanghai Duomu Industrial Co., Ltd. focuses on the research and development, production, and sales of advanced wear-resistant and corrosion-resistant automated equipment such as plasma powder welding machines, PTA welding machines, and laser cladding machines.

The automated cladding equipment exported to Malaysia this time adopts a modular design and high-precision machining technology to ensure the stability and repeatability of the core spray melting unit, control system, and feed system, meeting the demanding production requirements of the petrochemical, mining, and machinery manufacturing industries.

2. Strict inspection: comprehensive testing to ensure equipment performance meets standards

After the equipment was manufactured, the company's engineering team conducted multiple quality inspections on each piece of automated cladding equipment, including: overall equipment coordination and adjustment, cladding parameter calibration, temperature and energy response testing, and safety protection testing, to ensure that the equipment performance met the expected standards and achieved the goal of zero-fault operation.

3. Logistics and Shipping: Precise Coordination and Multilateral Guarantees for Safe Delivery

Based on the characteristics of international logistics, the company makes overall arrangements for special packaging and protective reinforcement, and cooperates with local customs clearance regulations in Malaysia to prepare for export. At the same time, it selects reputable sea/air freight partners to ensure that the equipment is delivered safely and quickly to the customer's designated location, achieving “zero omissions and zero damage” delivery from the factory to the customer's warehouse.

4. Installation, commissioning, and acceptance: Assisting customers with smooth production start-up

Upon arrival of the equipment, Duomu Industrial's on-site engineers will work with the customer's technical team to complete equipment installation, pipeline connection, electrical commissioning, and initial trial operation. The acceptance process focuses on testing equipment stability, cladding quality, and ease of operation to ensure that the customer's equipment can be immediately integrated into the production process.

5. Professional training: Improving customer operational proficiency and self-management capabilities

Duomu Industry provides systematic training services covering the following content:

- Cladding process principles and control parameters

- Operating interface and control system user manual

- Daily maintenance and maintenance procedures

- Common fault diagnosis and countermeasures

Through a combination of on-site training and various forms of media such as videos and manuals, we help customer operators quickly master equipment operation and maintenance skills, thereby improving equipment operational efficiency.

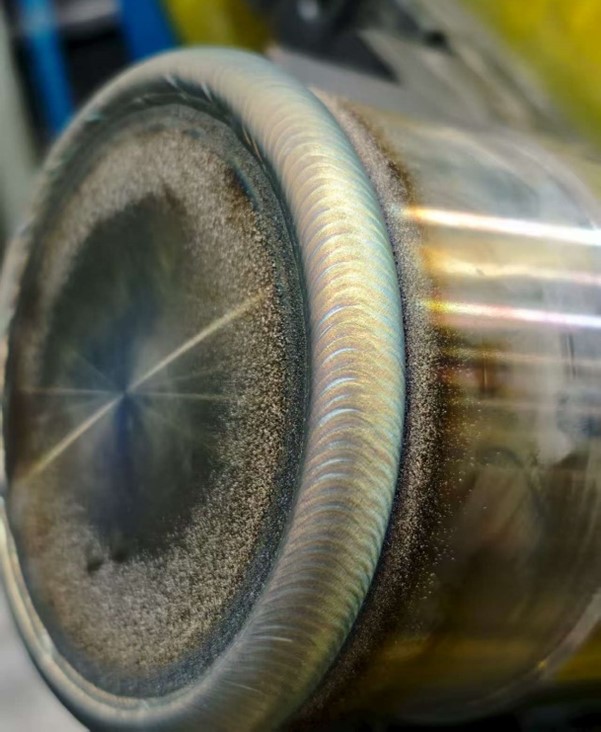

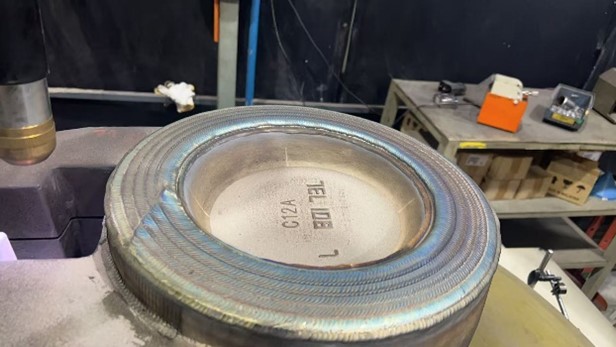

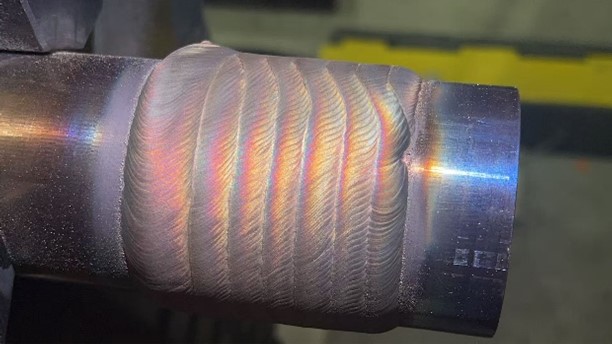

Live footage:

6. Customer feedback: High satisfaction wins trust and reputation

Customers have highly praised the automated cladding equipment provided in this project, as follows:

- “The cladding equipment supplied by Shanghai Duomu Industrial was delivered promptly, performs reliably, and the training provided was practical. The post-sales service response was timely, effectively enhancing our production efficiency.”

- “The installation and commissioning of the equipment went very smoothly. The Duomu engineers were professional and patient, providing significant assistance to our operational team.”

Customers have praised the equipment's process precision, reliability, and superior service, and look forward to collaborating with Duomu on more projects in the future.

Post time: Aug-20-2025