What is a PTA welding machine?

PTA welding machines (Plasma Transferred Arc Welding Machines) are high-precision surface strengthening equipment that utilize a high-energy plasma arc as a heat source to melt metal powder and uniformly deposit it onto the workpiece surface.

Compared to traditional welding methods, PTA welding machine achieves metallurgical bonding, high hardness, and high-density surface strengthening layers, endowing workpieces with superior wear resistance, corrosion resistance, and fatigue resistance.

In modern manufacturing, PTA welding technology is widely applied in industries such as petroleum drilling tools, screw conveyor blades, conveying screws, valve sealing surfaces, pump shafts, and mold repair, serving as core equipment for surface engineering strengthening.

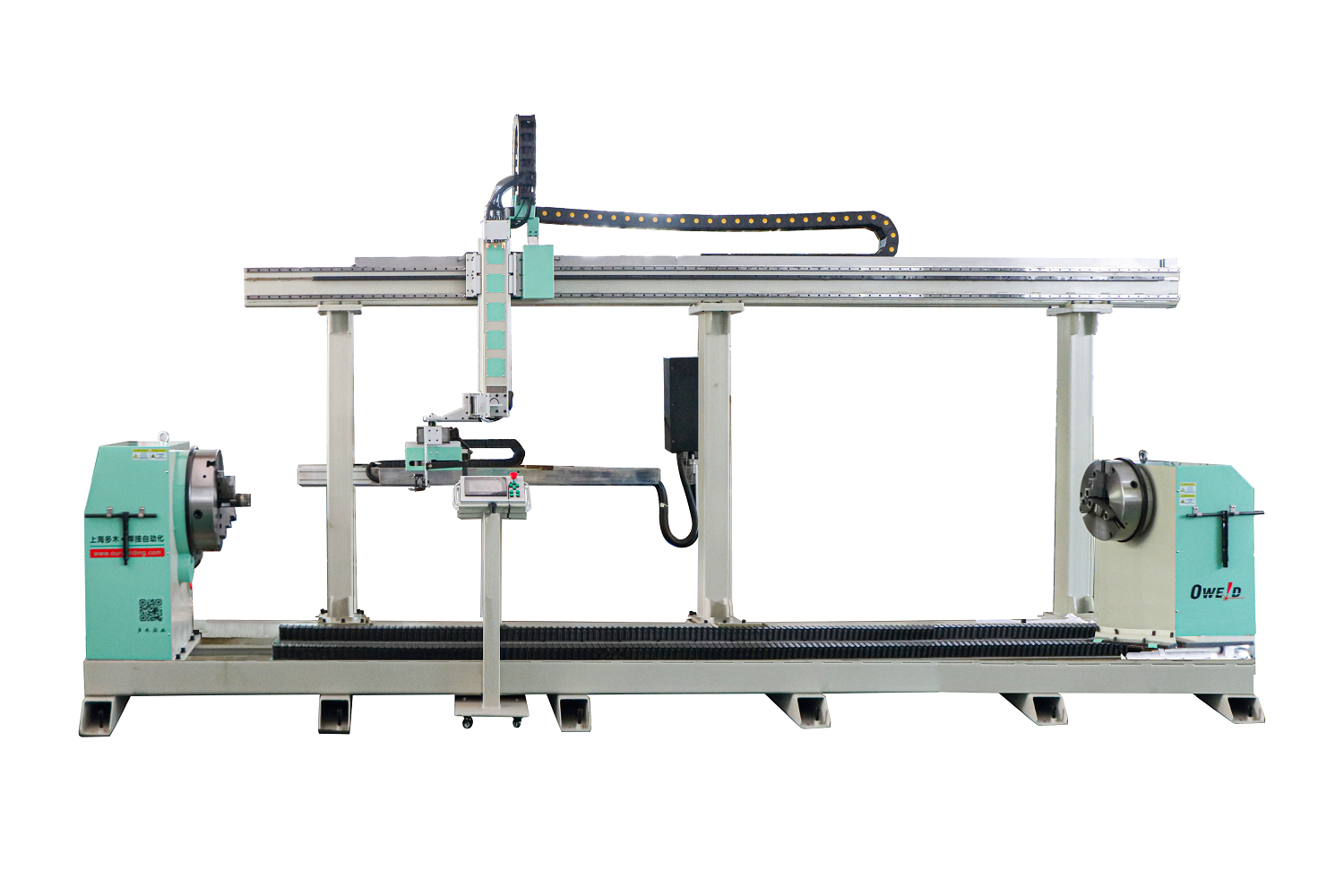

Automated PTA welding machine for Screw Blades

The automated PTA welding machine for screw blades is an intelligent cladding system developed specifically for complex curved components such as screw blades, propellers, and conveyor screws.

This machine utilizes PTA welding principles, employing a CNC system to control workpiece rotation, feed rate, pitch, and automatic powder feeding, enabling continuous and uniform automated overlay welding on helical surfaces.

The system integrates high-energy plasma arc welding with CNC helical trajectory control and a precision powder feeding system, efficiently performing wear-resistant and corrosion-resistant reinforcement overlay welding on helical components. It is an ideal solution for industries including energy equipment, marine propulsion systems, and metallurgical machinery.

Working Principle of PTA Welding Machine

1. Arc Formation: The main arc generates high-temperature plasma between the tungsten electrode and the workpiece, reaching temperatures exceeding 16,000°C.

2. Powder Feeding: Alloy powder (Ni-based, Co-based, Fe-based, etc.) is fed into the plasma arc via a precision powder delivery system.

3. Metallurgical Bonding: Melted powder forms a dense metallurgical bond layer with the workpiece surface within the arc zone.

4. Helical Automatic Operation: The control system coordinates rotational and axial feed movements to achieve continuous helical surfacing.

5. Cooling and Protection: The water-cooling system and shielding gas operate simultaneously to ensure stable and reliable welding quality.

Components of Automated PTA welding machine

1.PTA Welding Host System

- High-stability plasma welding power source (independent control of main arc and arc striking)

- PTA Welding Torch (Built-in Water-Cooled Circulation System)

- Automatic Powder Feeder (Constant Flow Powder Feeding, Adjustable Speed)

2.Automated Control System

CNC or PLC controllers enable multi-axis coordination and helical path control

HMI interface provides real-time monitoring of welding parameters

Automatic pitch, speed, current, and voltage control ensure precise cladding accuracy

3. Motion Execution System

Workpiece Rotation Drive Unit (Precision servo motor control)

Welding Torch X/Y/Z Three-Axis Interlocking

Automatic Height Adjustment and Tracking System, maintaining consistent welding gap

4. Auxiliary Systems

Industrial Water Cooling System

Shielding Gas Supply (Ar/Ar+H₂)

Welding Fume Purification System

Data Acquisition and Quality Traceability Module (Optional)

Advantages of PTA Welding Machines

1. High-Precision Spiral Automatic Cladding

CNC servo systems precisely control rotation and feed rates to achieve fully automated spiral trajectory cladding. This ensures uniform interlayer overlap and consistent weld layer thickness.

2. Superior Weld Layer Properties

PTA welded layers feature metallurgical bonding, delivering high hardness, high density, and strong resistance to spalling. They withstand prolonged exposure to high loads and corrosive environments.

3. Energy-Efficient and High-Performance

Automated continuous welding eliminates manual intervention, significantly reducing labor costs and material waste.

4. Wide Applicability

Suitable for diverse materials (carbon steel, stainless steel, Inconel, Stellite, NiCrBSi, etc.) and various workpiece geometries.

Typical Application Areas

• Weld overlay strengthening for marine propeller blades

• Wear-resistant layer restoration for oil and gas drilling tool spiral blades

• Weld overlay strengthening for conveying screws and extrusion screws

• Surface anti-wear weld overlay for concrete mixer spiral blades

• Corrosion-resistant layer weld overlay for pump bodies, valves, and mold components

The automated PTA weld overlay process significantly enhances the surface properties and service life of spiral components while reducing maintenance and replacement costs.

Automated PTA welding machine for screw blades integrates high-energy plasma welding technology, intelligent control systems, and automated motion technology, serving as a critical piece of equipment for high-end surface strengthening in modern manufacturing.

Whether for new part production or refurbishing existing components, this equipment delivers highly efficient, high-quality, and consistent cladding results.

Interested in PTA welding machine? Click here.

Post time: Oct-10-2025