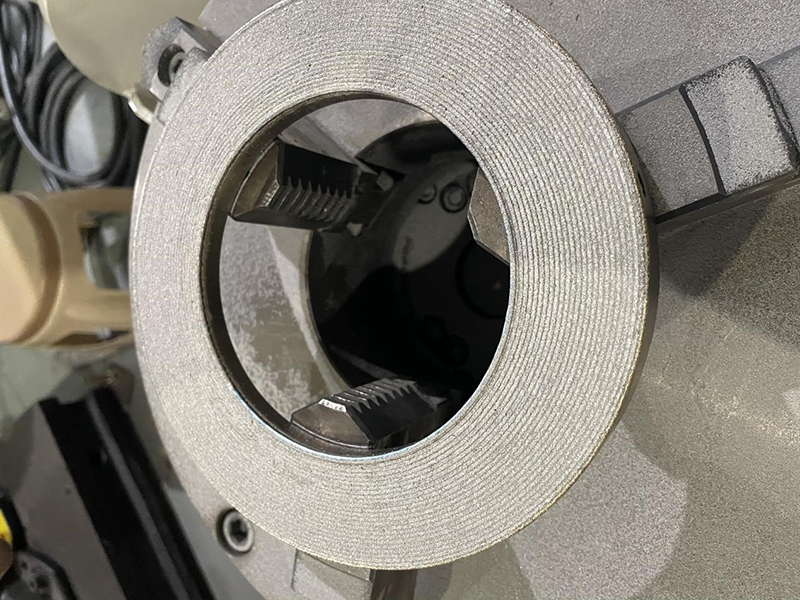

The laser metal deposition (LMD) process is a direct energy deposition process. Laser metal deposition is an additive manufacturing process where a laser beam is used to form a melt pool on the surface of a metal object. Metal powder is then injected using a gas stream.

A thin layer of the base material is melted by the laser heat source in a controlled way. This ensures that a metallurgical bond is created between the coating and the base material. The deposit material can be transferred to the substrate by injecting powder or by feeding a wire.

Laser metal deposition is used to produce and repair high-value parts and components. The process generates high-quality claddings and coatings with a lifetime of parts that partially extends the durability of galvanic coatings. The laser metal deposition process is used for applications in the offshore, oil and gas, aerospace, power generation, automotive and utilities industries.

Using laser metal deposition for repair has several benefits. Highly complex parts can be repaired with automated methods, and because of the low heat input, the heat-affected zone is kept small and thus the strength of the material is preserved intact.

Shanghai Duomu Industry Co., Ltd has been a leading manufacturer and exporter of PTA cladding machine and Laser metal deposition for more than ten years with a strong technical background.

Our mission is to provide advanced machine with an affordable cost to meet customer's needs of solution of wear and corrosion.

We devoted ourselves to offer the machine that would have a comprehensive solution to wear and corrosion for customers.

Our team, Shanghai Duomu Industry consists of a young and dynamic and specialized team. We fight tooth and nails to create reliable, cost-effective and customized solutions for our customers. Mechanical Engineers and Technicians work at the state-of-art workshop facilities day and night.

Post time: Jul-21-2023