In today’s construction machinery industry, the performance and life span of cut-off gears, as a key wear-resistant component, have a direct impact on project efficiency and cost. The latest application of laser cladding technology has become the leading technology for surface treatment of cut-off gears. Through innovative laser processing means, the wear resistance of cut-off gears has been significantly improved, their service life has been prolonged, and they have shown great potential in the fields of mining, tunneling and civil engineering.

Core advantages of laser cladding technology

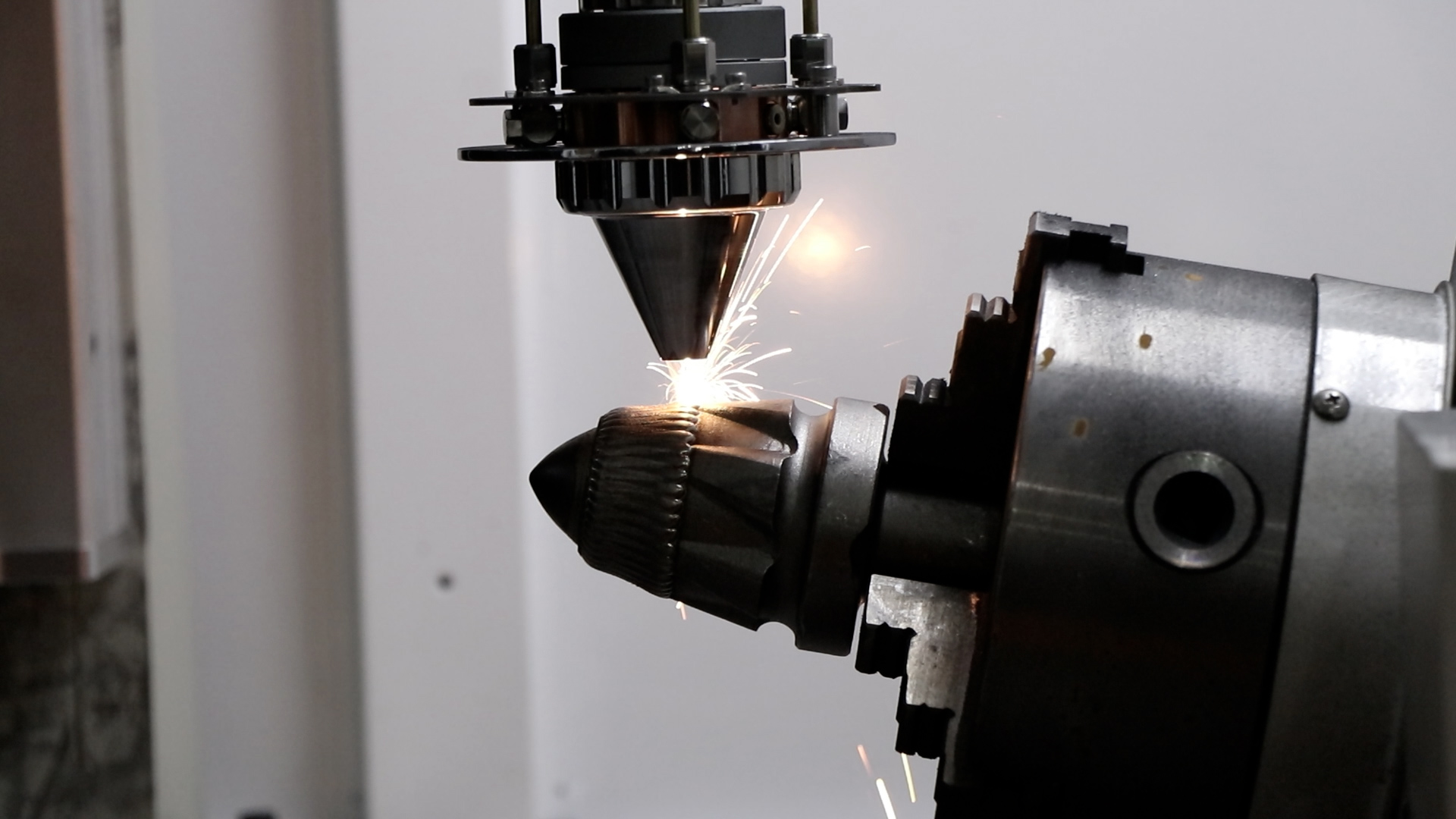

Laser cladding technology utilizes a high energy density laser beam to melt powdered or filamentary additive materials, which are rapidly bonded to the surface of the base material of the tooth to form a new material layer. The application of this technology brings several significant advantages:

1.

**Improve wear resistance**: The fusion cladding material is usually selected from high hardness materials such as cemented carbide, high chromium iron, etc., which makes the treated surface hardness of the cut-off teeth increase dramatically, effectively resisting abrasion.

2.

**Enhancement of corrosion resistance**: Laser cladding can form a dense protective layer on the surface of the tooth, preventing the erosion of moisture and corrosive substances.

3.

**Precise control and high efficiency**: Laser cladding can precisely control the thickness and composition of the overlay layer to ensure that each tooth meets the designed performance specifications. At the same time, the processing speed of laser cladding is fast, which greatly shortens the production cycle.

4.

**Energy saving and environmental protection**: Compared with traditional electroplating or chemical plating, the laser cladding process produces almost no waste and is more environmentally friendly.

Wide range of industry application prospects

With the maturity and popularization of laser cladding technology, its application in the manufacture of cut-off teeth is becoming more and more extensive. In the mining industry, laser cladding can effectively cope with the complex and variable geological environment and improve the mining efficiency. In tunneling and civil engineering, the technology improves the reliability and safety of machinery and equipment, reduces maintenance and replacement frequency, and saves a lot of time and cost for projects.

Looking to the future

The continued development and innovation of laser cladding technology will further drive technological advances in the cut-off gear and the construction machinery industry as a whole. By combining with other advanced manufacturing technologies such as 3D printing, the future of laser cladding technology will be more diversified and intelligent, bringing more possibilities to the construction machinery industry. With the continuous optimization of technology and further cost reduction, laser cladding will be more widely used worldwide, bringing revolutionary changes to more industries.

Technology Innovation and Market Reaction

Market acceptance of laser cladding technology is so high that several leading construction machinery manufacturers have already begun to incorporate this technology into their core product lines. By offering more wear-resistant and longer-lasting cut-off teeth, companies are able to provide higher value to their customers, thus gaining an edge in the highly competitive market. In addition, with the tightening of environmental regulations and the industry’s pursuit of sustainable development, laser cladding technology is becoming an important market driver due to its environmentally friendly characteristics.

Policy Support and Industry Development

The government has given strong support to the R&D and application of high and new technology, including tax incentives, financial support and policy guidance, etc., which have greatly promoted the research and development of laser cladding technology. The establishment and improvement of industry standards are also being synchronized to ensure the safety and reliability of the technology application, laying the foundation for the extensive promotion of the technology.

The Role of Education and Training

As the complexity of the technology increases, so does the demand for specialized technical personnel. Higher education institutions and vocational and technical schools have begun to add relevant courses to train personnel for the operation and maintenance of laser cladding technology. At the same time, the cooperation between enterprises and academic institutions is getting closer and closer to promote the practical application of the technology and the practical training of talents.

Conclusion

The application of laser cladding technology in the manufacture of cut-off teeth is a great innovation in the field of construction machinery. It not only improves the product performance and extends the service life, but also helps environmental protection, which is in line with the trend of future development. With the continuous progress of technology and further cost reduction, laser cladding will continue to expand its influence in the global construction machinery manufacturing industry, and promote the development of the whole industry in a more efficient and sustainable direction.

Surface cladding of cutting picks

Post time: Apr-22-2024