Mining pick is a coal mine coal mining machine and mine tunnel boring machinery used in the cutting edge, mining pick quality advantages and disadvantages directly affect the efficiency of the mining machine and the production cost of enterprises, with the increase in demand for energy, especially coal, in order to improve the efficiency of mining, coal mining machine power continues to increase, the quality of mining picks more and more high, as coal mining machine mining picks material, it is required to have a high strength, hardness and abrasion resistance, high Bending strength and corrosion resistance, in order to prevent the use of mining picks in the process of fracture, bending, deformation and early wear and tear.

The general classification of mining picks are: coal mining teeth, digging teeth, rotary digging teeth, etc.

At present, domestic and foreign commonly used mining pick material alloy series are mainly Cr-Mo system, Mn-B system, Cr-Ni-Mo system, Cr-Mn-Si system, Si-Mn-Mo system, etc. From the production method of the main casting mining pick material and forging mining pick material.

The production process of mining picks can be divided into 3 types

(1) The body of the pick is processed and shaped, brazed carbide head, heated in a salt furnace, isothermal quenching with nitrate salt and tempered.

(2) The mining pick body processing and molding a salt furnace heating a nitrate salt isothermal quenching a cleaning a + brazing carbide head a tempering.

(3) Brazing-heat treatment integration technology.

(1) Surfacing carbide. Mining pick wear-resistant layer of surfacing is the use of the surfacing material with high hardness and high wear resistance, in the head of the mining pick teeth body surfacing one or several layers of surfacing material, forming a protective belt, the layer has a high abrasion resistance, good corrosion resistance, so that the tooth head of the mining pick pants body material is not in direct contact with the coal rock being mined to reduce the tooth head of the body of the library material and the coal seam of the friction and impact and other roles, slowing down the wear and tear failure rate of the picks to extend the picks Service life. Surfacing has the advantages of simple equipment, low cost, more flexible operation, and can adapt to a full range of surfacing.

(2) surface thermal spraying. Another method of surface treatment of mining picks is to use thermal spraying technology to improve the wear resistance and service life of the head part of the mining pick. Such as the head of the mining pick material high temperature spraying a layer of metal ceramics, increase the hardness of the head (HRC ≥ 60), high hardness, good wear resistance, the service life of the mining pick can be increased by more than 50%!

(3) Surface metallurgy methods. Surface metallurgy technology is a plasma arc as a heat source, the surface of the substrate material to obtain a layer of uniformly dense, combined with a strong special protective coating, to achieve the metallurgical bonding of the coating and the metal substrate, plasma cladding is a rapid non-equilibrium solidification process, with a supersaturated solid solution reinforcement, dispersion reinforcement and precipitation reinforcement and other reinforcing effects, the metallurgical layer obtained has a very high abrasion, corrosion, high temperature oxidation resistance. Performance.

(4) Chemical heat treatment. Chemical heat treatment is the surface of the mining picks carburization, boron infiltration, chromium infiltration and other chemical heat treatment, so that the surface of the mining picks to form a higher hardness compounds to enhance the surface wear resistance. Through the 40CrNiMo boronizing and chromium treatment, the surface of the formation of boron and chromium compounds to improve the surface hardness and wear resistance, so that the service life of mining picks can be improved.

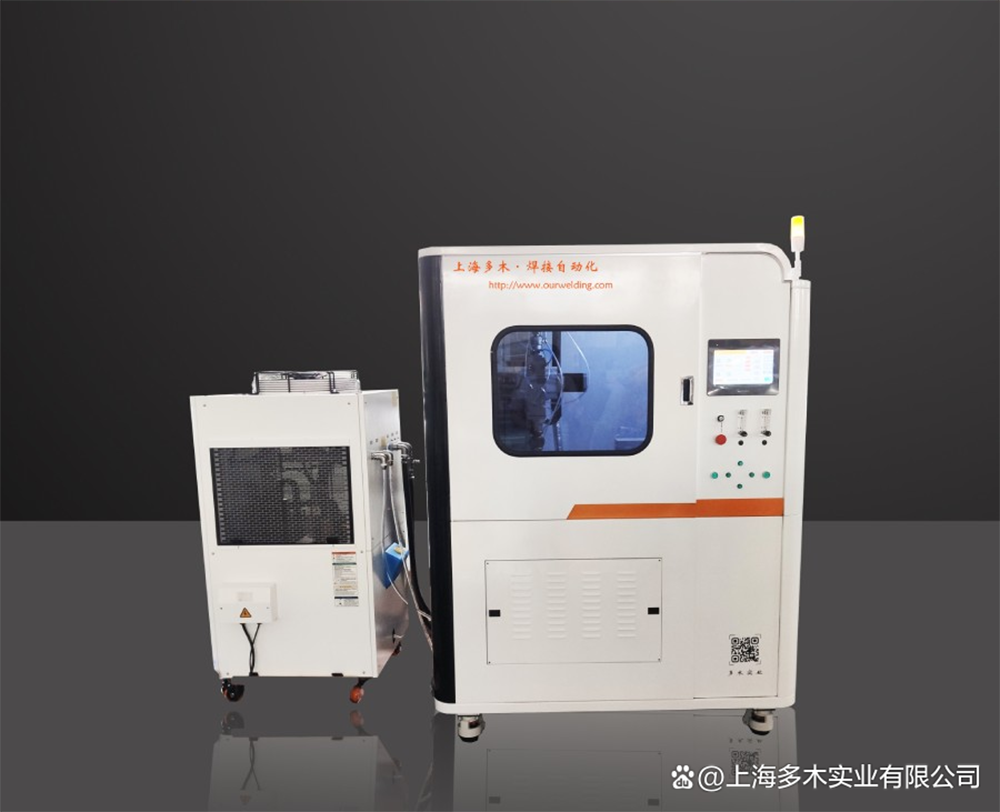

Laser cladding process for mining picks

Utilizing laser as a heat source to melt the powder on the surface of the workpiece, metallurgical bonding, with high bonding strength and low dilution rate. Laser cladding is a new surface modification technology. The principle is to use high-density laser beam with different composition, properties of the alloy and the surface of the substrate rapid melting, the formation of the substrate surface and the substrate has a completely different composition and properties of the alloy layer of the rapid solidification process, compared with the surfacing, spraying, plating and other traditional methods have a small dilution rate, tissue density, coating and substrate bonding, suitable for the fusion of more materials, particle size and content of the large changes in the characteristics of the material.

Laser cladding mining picks have the characteristics of wear resistance, long life, not easy to break, no sparks. Not only reduces the cost of coal production, reduces the labor intensity of workers, but also a good solution to the long-standing problem of threatening the safe production of coal because of the use of mining picks in the process of generating sparks, the application of laser cladding materials so that the mining picks cladding layer performance indicators and cladding layer shape with versatility and controllability; laser cladding materials and cladding process application, a complete solution to the brazing process on the tooth head caused by the annealing softening Problems.

Post time: Sep-11-2023