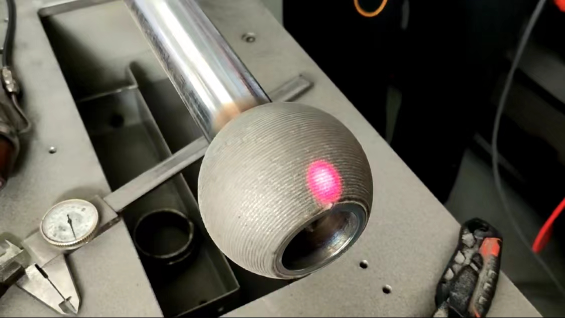

How to surfacing the ball Valve by Laser

Shanghai Duomu has an abundentful experience in cladding the ball valve due to our technical team to dive into researching day and night. We help a lot of ball valve manufacturers for saving a large amount of cost.

This vedio introduce briefly the course of ball valve process. We used the power supply 6 KW, the diameter of the ball valve: 100 mm, thinkness: 1 mm, time: 10 minutes, surfacing material: Cobalt base alloy powder.

Not only would our laser power supply be a configuration with the PTA welding tooling which is customized, robot but also it would have done by hand. This tooling in the video is unique for the ball valve. In the video, the robot KUKA is configurated with the laser power 6KW that increases greatly the performance. And shortened the completion time significantly.

The brand of laser power supply Raycus we adopted is the from reputation domestic company which is the top in Asia. Compared with the European brand, it has an excellent capability and an affordable cost.

However, it would customized as your requirement, such as the robot of four family, except for the KUKA, the ABB, FANANC, YASKAWA, as well as the domestic operator if you like the more cost-effective equipment.

Video

Post time: Sep-30-2022