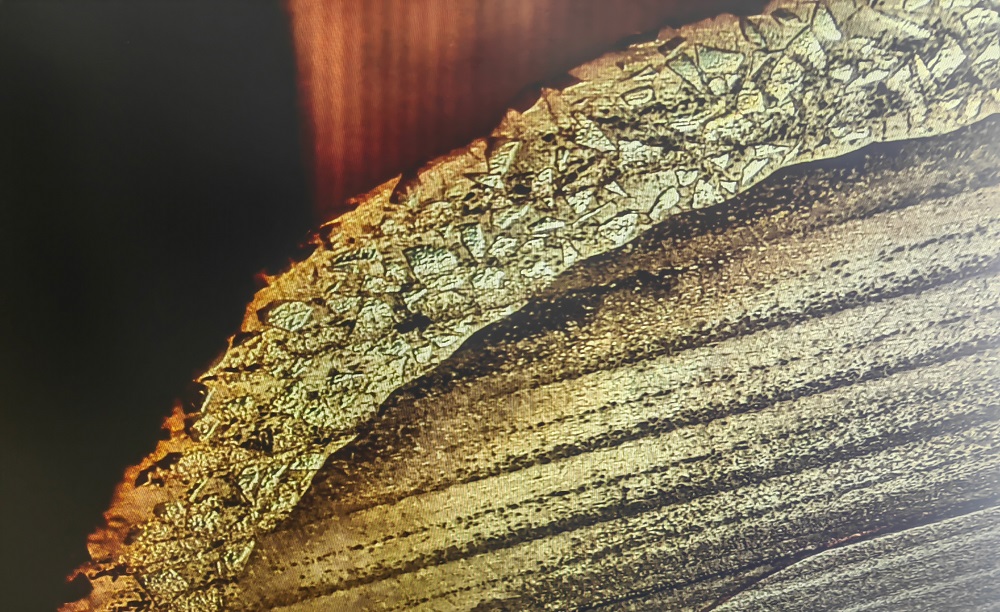

Tungsten carbide hardfacing is a surface strengthening process in which high-hardness tungsten carbide (WC) material is deposited onto the surface of components to form a wear-resistant layer firmly bonded through welding. This technique significantly improves the durability of metal parts under abrasive, high-impact, and corrosive conditions, greatly extending equipment service life.

What is Tungsten Carbide Hardfacing?

Tungsten carbide (WC) is a superhard material second only to diamond. By applying it to a metal substrate through hardfacing, a surface armor layer is formed, achieving surface hardness of HRA 88–94, while the underlying metal substrate still provides toughness and structural strength.

In simple terms:

The substrate provides structural support.Tungsten carbide provides wear resistance.This combination achieves an optimal balance of strength and durability.

Why Use Tungsten Carbide Hardfacing?

In many types of equipment, wear is the primary cause of downtime and part replacement. Tungsten carbide hardfacing enhances the durability of critical wear areas, reducing maintenance and replacement costs.

Types and Characteristics of Tungsten Carbide

Common forms of tungsten carbide include:

- Cast Tungsten Carbide: Excellent toughness, suitable for impact-heavy wear conditions

- Sintered Tungsten Carbide: Extremely hard, ideal for severe abrasive environments

- Composite Tungsten Carbide Alloys: More stable in corrosive and high-temperature applications

- Spherical Tungsten Carbide Particles: Superior weldability and bonding quality

Depending on the application, these forms can be used individually or in combination for optimal performance.

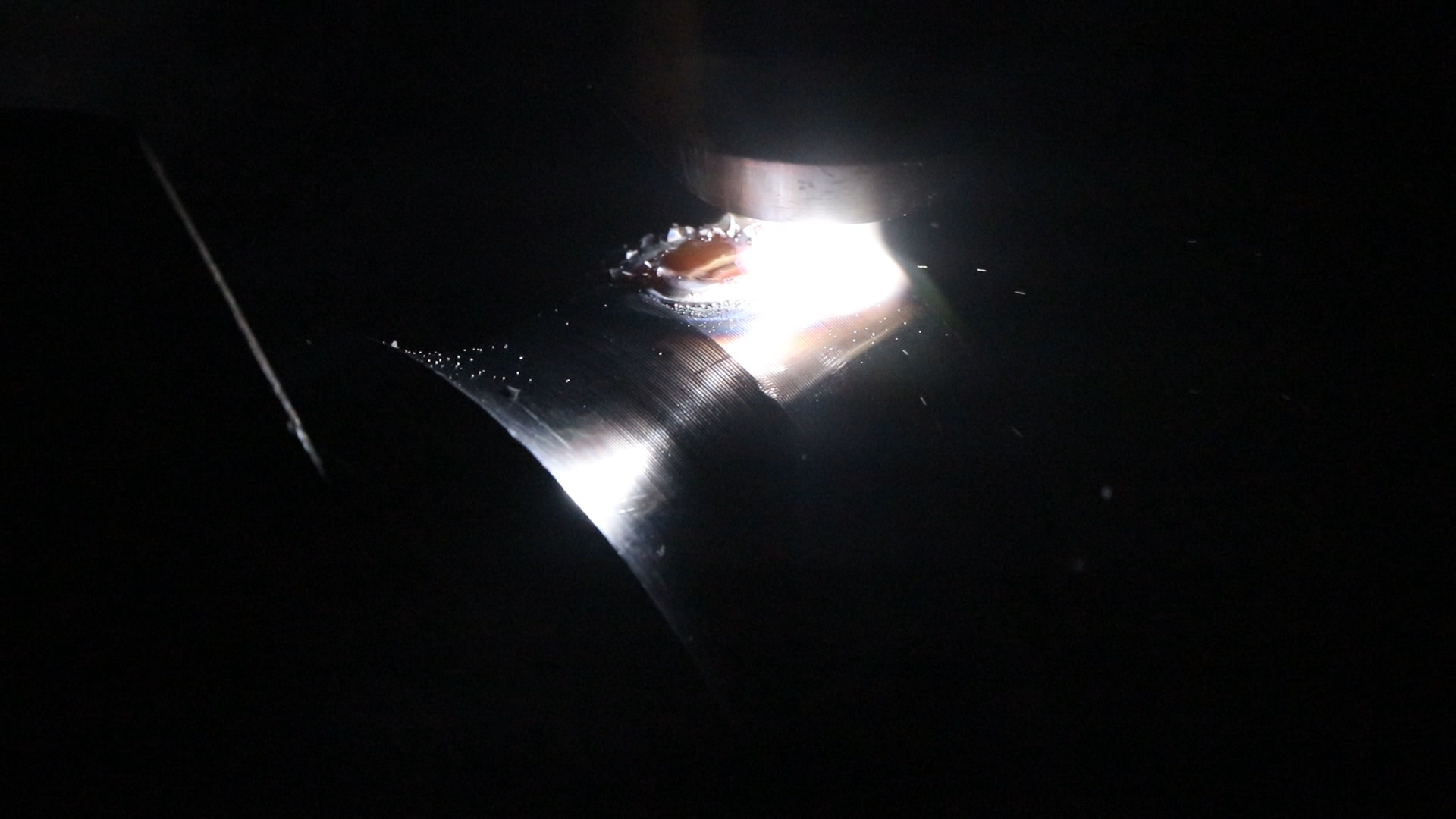

Common Welding Processes for Tungsten Carbide Hardfacing

Tungsten carbide hardfacing can be achieved through various welding methods:

• Plasma Transferred Arc (PTA) Hardfacing: Low dilution, highly stable wear resistance

• GTAW / TIG: High precision, ideal for small areas or high-spec components

• GMAW / MIG: High efficiency, suitable for both manufacturing and on-site repair

• Oxy-Fuel Flame Hardfacing: Suitable for rapid reinforcement of large construction equipment

• The choice of method depends on cost, efficiency, and desired service life.

Typical Applications of Tungsten Carbide Hardfacing

Tungsten carbide hardfacing is suitable for any component subjected to severe abrasive or impact wear, including:

- Mining Equipment: Bucket teeth, breakers, liners, conveyor components

- Oil Drilling Tools: Drill bits, stabilizers, wear-resistant joints, friction rings

- Construction Equipment: Mixer blades, pump pipes, screw conveyor flights

- Agricultural Machinery: Plowshares, trenching blades, seed drill wear parts

Anywhere severe wear occurs, tungsten carbide hardfacing proves its value.

Frequently Asked Questions

Q: Will the hardfacing layer peel off?

A: No. When proper welding heat input and particle embedding are ensured, the bond is extremely strong. Cracking or delamination usually results from improper technique.

Q: What is the typical thickness of the hardfacing layer?

A: Thickness depends on the working conditions, typically 2–10 mm. For extreme wear, multiple layers or optimized particle grades may be applied.

Q: Can the hardfaced layer be machined?

A: Yes, but it is challenging. It is recommended to control thickness and shape accurately before hardfacing to minimize post-machining.

Q: Is the cost higher than conventional hardfacing?

A: Material and welding costs are higher, but the significantly longer service life makes it more cost-effective overall, representing the most economical wear-resistant solution for enterprises.

Tungsten carbide hardfacing is one of the most effective and economical surface strengthening solutions in heavy-duty industries worldwide. It provides longer equipment life, reduced downtime, higher production stability, and better overall operational costs. It is ideal for high-wear critical areas and is a key technology for enhancing competitiveness.

Contact us to learn more about tungsten carbide hardfacing processes and surface treatment solutions.

Post time: Oct-24-2025