In the fields of surface strengthening, component repair, and service life extension for industrial equipment, hardfacing and thermal spraying are two widely used surface treatment processes. Many users often wonder: What is the difference between the two? Which technology is more suitable for my equipment? This article will comprehensively analyze the fundamental differences, application scenarios, and performance advantages of hardfacing and thermal spraying through a professional Q&A format, helping readers make informed decisions.

What is hardfacing? What is its basic principle?

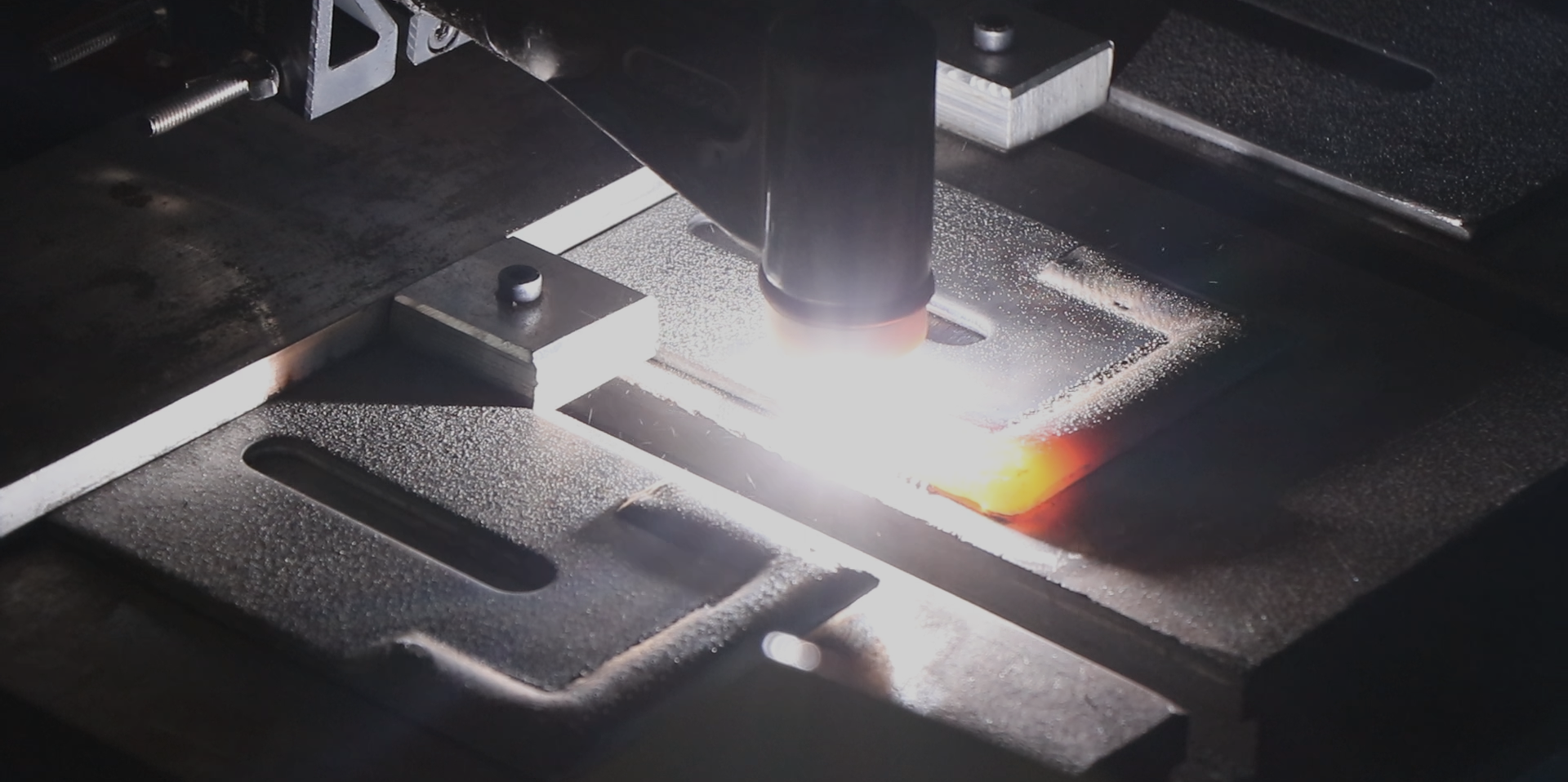

Hardfacing is a surface strengthening technology that uses electric arcs, lasers, or plasma heat sources to melt wear-resistant, corrosion-resistant, or high-strength alloy materials and fuse them with the base metal to form a coating. It is characterized by metallurgical bonding, thick coatings, and strong adhesion, with a typical thickness of 1 to 10 mm.

What is thermal spraying? How does it differ from hardfacing?

Thermal spraying is a process in which powder or filamentary materials are heated to a molten or semi-molten state and sprayed onto the surface of a substrate by a high-speed gas stream to form a protective coating. The biggest difference between thermal spraying and hardfacing is the method of bonding: thermal spraying is mechanically bonded rather than metallurgically bonded, and the layer thickness is generally 0.05 to 0.5 mm.

In terms of wear resistance, is hardfacing better or thermal spraying stronger?

Hardfacing has better wear resistance because of its high metallurgical bonding strength and material hardness of HRC 50 to 65, making it particularly suitable for equipment repair and reinforcement under conditions of strong abrasive wear, intermetallic impact, and high pressure.

Although thermal spraying can also achieve a hardness of HRC 60 or above (such as WC-Co spray coating), due to its low bonding strength (only 10-70 MPa), there is a risk of coating spalling when subjected to impact or sudden changes in load. Therefore, hardfacing should be considered first in heavy-duty, high-stress situations.

Is thermal spraying superior to hardfacing in terms of corrosion protection?

Yes. Thermal spraying is suitable for corrosion protection, especially in:

• Acidic and alkaline gas environments

• Marine salt spray environments

• High-temperature oxidation environments

It can use a variety of corrosion-resistant spray materials, such as stainless steel, nickel-based alloys, ceramic oxides, aluminum, zinc, and other materials, to form a dense coating.

In contrast, hardfacing is mostly used for wear protection. Although there are corrosion-resistant welding materials (such as Inconel, Hastelloy, etc.), they are relatively expensive and have a high risk of heat damage.

Which technology is more suitable for thin-walled or high-precision workpieces?

Thermal spraying is more suitable for thin-walled and precision workpieces.

Due to the low heat input of thermal spraying, it causes almost no deformation of the workpiece and does not alter the properties of the substrate, making it ideal for surface treatment of complex parts.

Hardfacing causes high heat and deep heat affect, so if it is used without sufficient heat treatment, it can easily cause cracking, deformation, or weld defects in the workpiece.

Which has a longer service life?

Hardfacing has strong bonding strength, thick layers, and high hardness, and generally has a longer service life, especially under heavy loads and impact conditions.

The service life of thermal spraying depends on the working conditions and material selection, and is suitable for periodic maintenance and controlled environments.

Which is more cost-effective, hardfacing or thermal spraying?

- Hardfacing: High initial investment and long processing time, but long maintenance cycle and low total cost.

- Thermal spraying: High construction efficiency and low single cost, but suitable for light loads and may require frequent maintenance.

Therefore, if short-term rapid repair or large-area protection is required, thermal spraying is the preferred choice; if long-term stable operation is required, hardfacing is more cost-effective.

Can surfacing and thermal spraying be used simultaneously?

Of course! In some high-demand situations, such as restoring structural strength through surfacing first, then spraying a ceramic or alloy layer to enhance corrosion resistance, the advantages of both can be fully utilized to achieve composite surface reinforcement and increase service life.

What are the obvious limitations of thermal spraying?

Although thermal spraying is widely used in light-duty protection and corrosion-resistant applications, it is not suitable for all industrial scenarios, particularly due to the following limitations:

• Prone to peeling: The coating is prone to cracking or delamination under impact or high-load conditions;

• Inability to withstand abrasive erosion: Its wear resistance is significantly lower than that of welded layers;

• Short service life: Frequent maintenance or re-coating is required;

• Limited surface functionality: It cannot enhance structural strength and is limited to surface protective functions.

For large-scale critical equipment requiring prolonged, continuous operation, these defects are clearly unacceptable.

Why is hardfacing more reliable in high-wear equipment?

Hardfacing is not just a surface “repair” but rather a true enhancement of the component's performance through metallurgical bonding. This is critical for components that are subjected to high-intensity abrasive erosion, high impact loads, and frequent friction. For example:

- Buckets, tooth plates, and liners in mining machinery

- Vertical mill rollers and grinding discs in cement plants

- Boiler tubes and coal mill components in thermal power plants

- Guide rolls, rolling rolls, and steel pushing devices in steel mills

In these situations, the demand for strong bonding and high hardness far exceeds the capabilities of thermal spraying, making hardfacing an irreplaceable technical choice.

How to choose between hardfacing and thermal spraying?

Hardfacing and thermal spraying each have their own advantages. It is not a question of which is better, but which is more suitable for your working conditions and objectives. Understanding the working environment of the workpiece (wear, impact, corrosion, high temperature), material type, structural shape, and budget requirements is the key to formulating a reasonable process plan.

Both technologies have their advantages and disadvantages. Only by combining them reasonably or even using them in combination can equipment performance be maximized and costs optimized. If your equipment is suffering from severe wear and high downtime losses, hardfacing technology will be a more reliable, professional, and worthwhile investment.

If you have equipment repair or surface strengthening needs, please contact us. We provide complete hardfacing solutions, supporting customized services such as PTA plasma hardfacing, laser hardfacing, automatic hardfacing production lines, and on-site technical consulting.

Post time: Jul-29-2025