In recent years, laser welding has gained popularity due to its high precision and efficiency. As the demand for this technology continues to grow, the wide array of options on the market makes choosing the most suitable equipment difficult. The main factors to consider when choosing a laser welding machine include power, the type of material you plan to weld and, of course, budget. Let's take a closer look at what needs to be considered when making a decision so that the purchase of this expensive piece of equipment meets your expectations and becomes a long-term investment for your business.

What is laser welding technology?

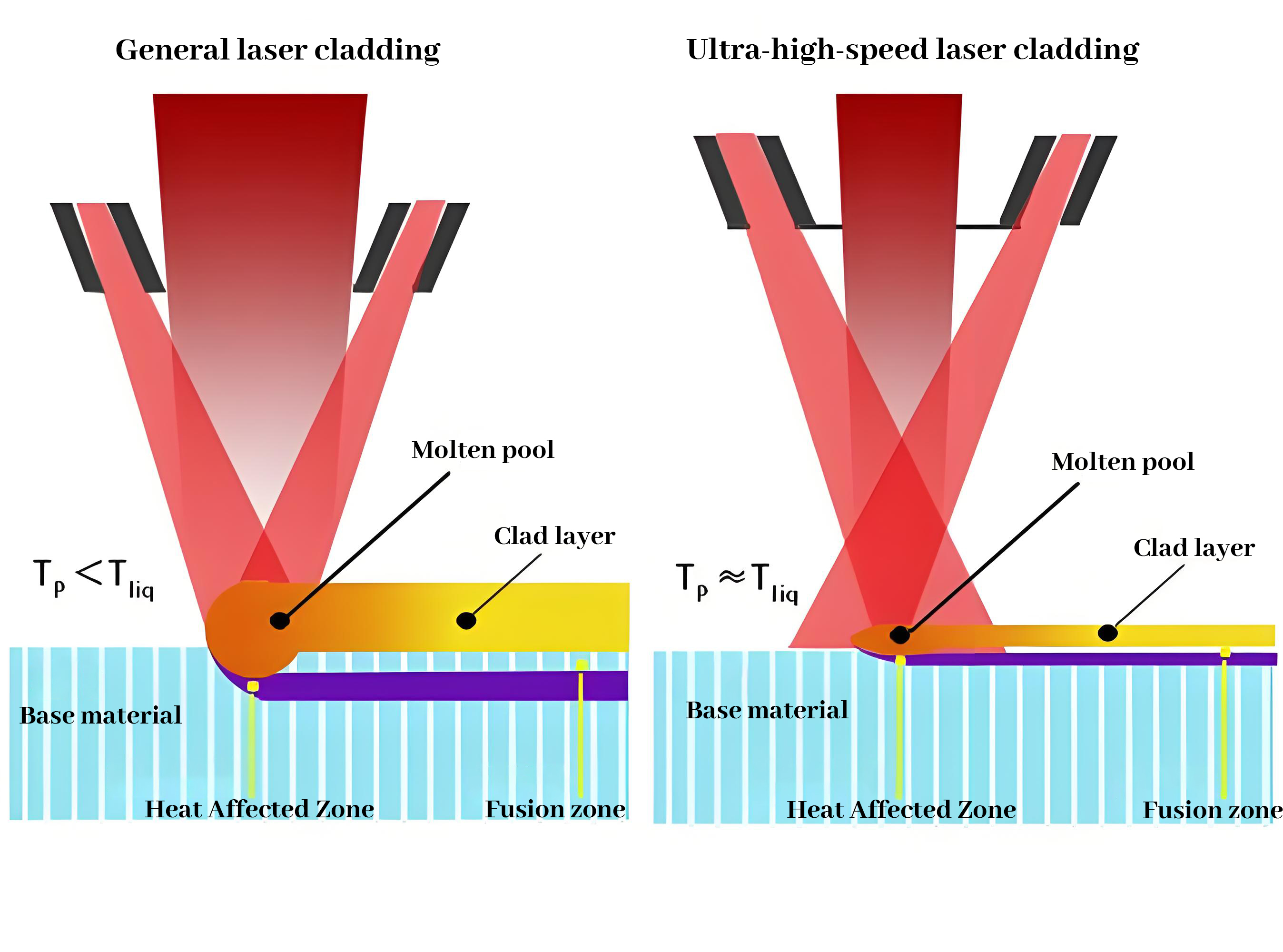

Before choosing a laser welding machine, it's important to understand how the technology works. Laser welding uses a high-energy beam to join metallic and non-metallic parts, which concentrates the energy in a very small area, resulting in a high-precision weld that minimizes the impact on the surrounding material. A major advantage of the technology is the ability to create strong and durable weld seams, making laser welding ideal for complex applications such as automotive, aircraft and medical.

Key Characteristics for Choosing a Laser Welder

When choosing a laser welding machine, it is important to consider the basic characteristics of the laser power, wavelength and type of cooling.The power, usually measured in kilowatts, determines the ability of the equipment to process different materials and thicknesses, and the wavelength influences the level of absorption of different materials, which is important when processing different types of metals and alloys. In turn, cooling ensures that the laser works stably and prevents overheating, and reliable cooling guarantees the durability of the equipment and the quality of the welding work performed.

Advantages and disadvantages of different types of lasers

There are different types of laser welding machines available in the market such as Co2 lasers, solid state lasers and fiber lasers. Each type of laser has its own unique advantages and disadvantages.Co2 lasers are known for their high power and efficiency in the processing of non-metallic materials. Solid-state lasers are compact, versatile and popular in small manufacturing environments. Fiber lasers, on the other hand, offer high beam quality and very low maintenance costs. They are most commonly used in industrial environments where high productivity and reliability are required.

Consider Cost and Profitability Factors

One of the most important factors affecting the selection of a laser welding machine is its cost. The initial acquisition cost of the equipment needs to be considered as well as operating costs such as energy consumption and consumable replacement costs. Profitability also depends on production volumes and the specific requirements of the business. An initial evaluation of the return on investment will help determine how profitable this acquisition will be for your production.

Tips for Choosing a Reliable Manufacturer

To ensure long-term operation, it is vital to choose a reliable manufacturer of laser welding machines. It is worth looking at the company's reputation, validity of certifications and warranty conditions. The service and support offered by the manufacturer is also crucial; choose a company that can provide training and assistance in the event of a technical failure. Customer testimonials and a long-term relationship with the manufacturer also contribute to confidence in the durability and quality of the equipment.

How to Make the Right Choice ?

Choosing a laser welding machine depends on a number of factors, including process capability, cost, and manufacturer reliability. Understanding your production needs will help you focus on what's most important to your business. Analyze all available options and make an informed decision to ensure a high-quality and efficient welding operation. Careful research and consultation with experts can make the selection process easier.

Post time: Jun-27-2025