Valvae triplices eccentricae partes magnas agunt in condicionibus laboris altae temperaturae, altae pressionis, et valde corrosivis in industriis petrochemicis, electricis, et metallurgicis. Superficies earum obturantes saepe deficiunt post operationem diuturnam propter detritionem, corrosionem, et erosionem.Methodi reparationis traditionales saepe vitam utilem limitatam habent, dumSoldatura arcus plasmatis transferentis (PTAW)technologia solutio praeferenda facta estReparatio superficierum obturantium valvulae triplicis eccentricaepropter magnam vim nexus et resistentiam attritioni atque corrosioni.

Quid est soldadura arcus plasmatis transferentis (PTAW)?

Soldatura per arcum plasmatis transferentem est technologia soldaturae metallurgiae pulveris altae densitatis energiae. Principium est ut arcu plasmatis utatur ad pulverem mixturae metallicae liquefaciendum (exempli gratia...).mixtura cobalti fundata, mixtura niccoli fundata, pulvis chalybis inoxidabilis, etc.) et eam magna celeritate in superficiem materiae sub actione gasis protectoris spargere ut stratum iuncturae metallurgicae cum dilutione parva cum metallo basi formetur. Haec methodus iuncturae efficit ut stratum superius habeat magnam firmitatem, densitatem, et excellentem resistentiam attritionis et corrosionis, idque aptissimum reddit ad...Tractatio valvularum altae temperaturae et altae pressionis resistentes attritioni.

Usus typici PTAW in valvis tripliciter eccentricis

In reparatione parium sigillorum valvularum tripliciter eccentricarum, PTAW imprimis adhibetur ad:

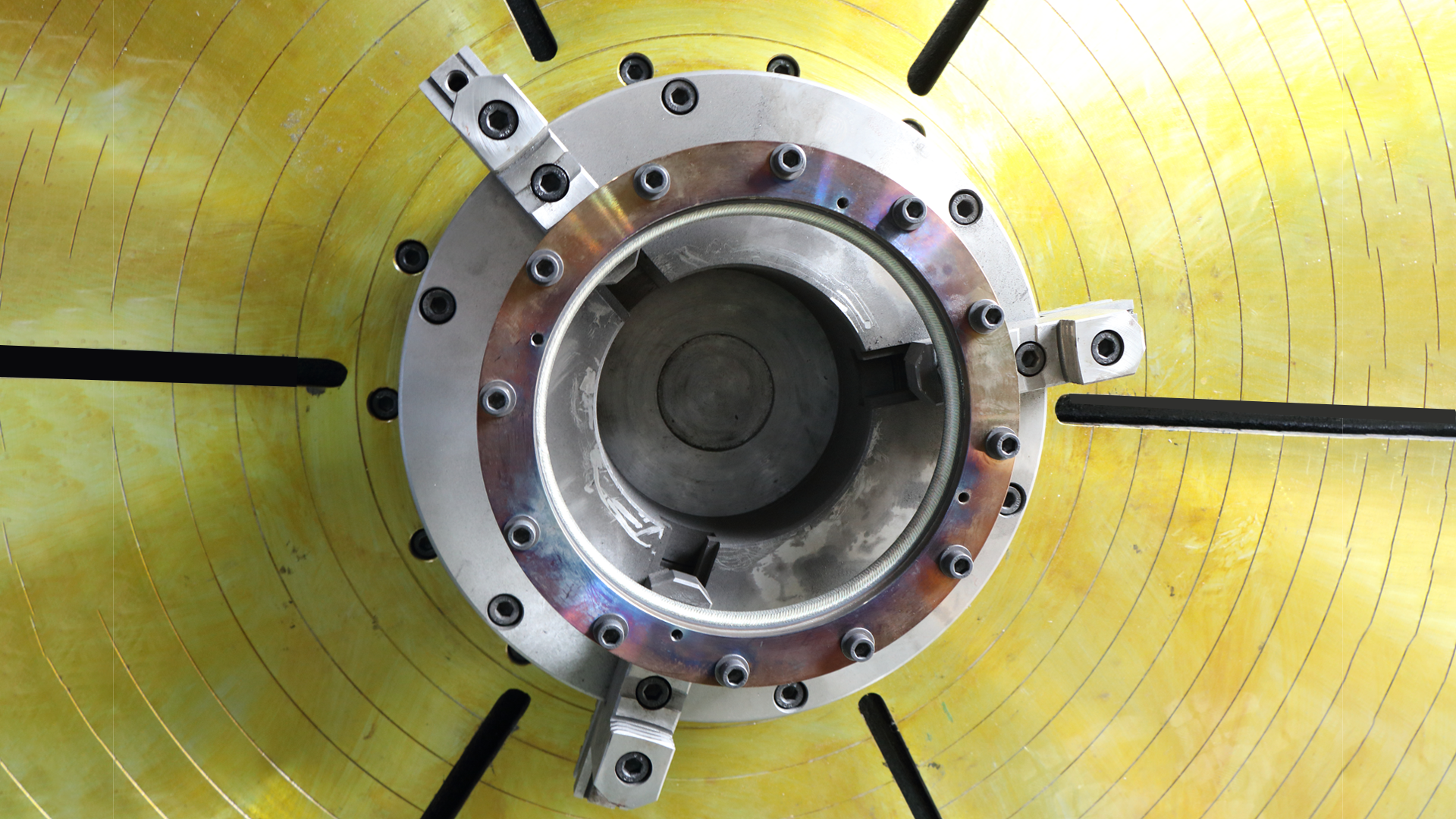

- Consutura superficiei obturantis sedis valvulae: ad stratum resistentiae detritioni magnae duritiae formandum.

- Tegumentum anuli obturantis laminae valvulae: ad frictionem minuendam et firmitatem obturantis augendam.

- Roboratio manicae et superficiei sustentatricis: ad prohibendum effluxum ex dilatatione rimae ortum.

Commoda soldadurae arcus plasmatis transferentis

Comparata cum methodis traditis ad ferruminandum, PTAW haec commoda insignes in reparatione valvularum tripliciter eccentricarum habet:

•Alta vis nexus: Methodus nexus metallurgica detractionem tunicae impedit.

•Dilutionis proportio humilis: Generaliter 3%–5%, effectus obductionis prope effectum originalem pulveris est.

•Indumentum densum: Porositas humilis et resistentia corrosionis magna.

•Excellens resistentia attritionis: Praesertim stratum soldadurae valvulae e mixtura cobalti fundatum, quod aptum est ad ambientes erosionis et frictionis.

•Alta praecisio processus: Crassitudo et positio obductionis moderari possunt, cum parva zona calore affecta, deformationem ad minimum reducens.

•Adaptabilis structuris complexis: Superficies obturantes complexas, ut superficies conicas et annulares valvularum trium partium distantium, accurate tegere potest.

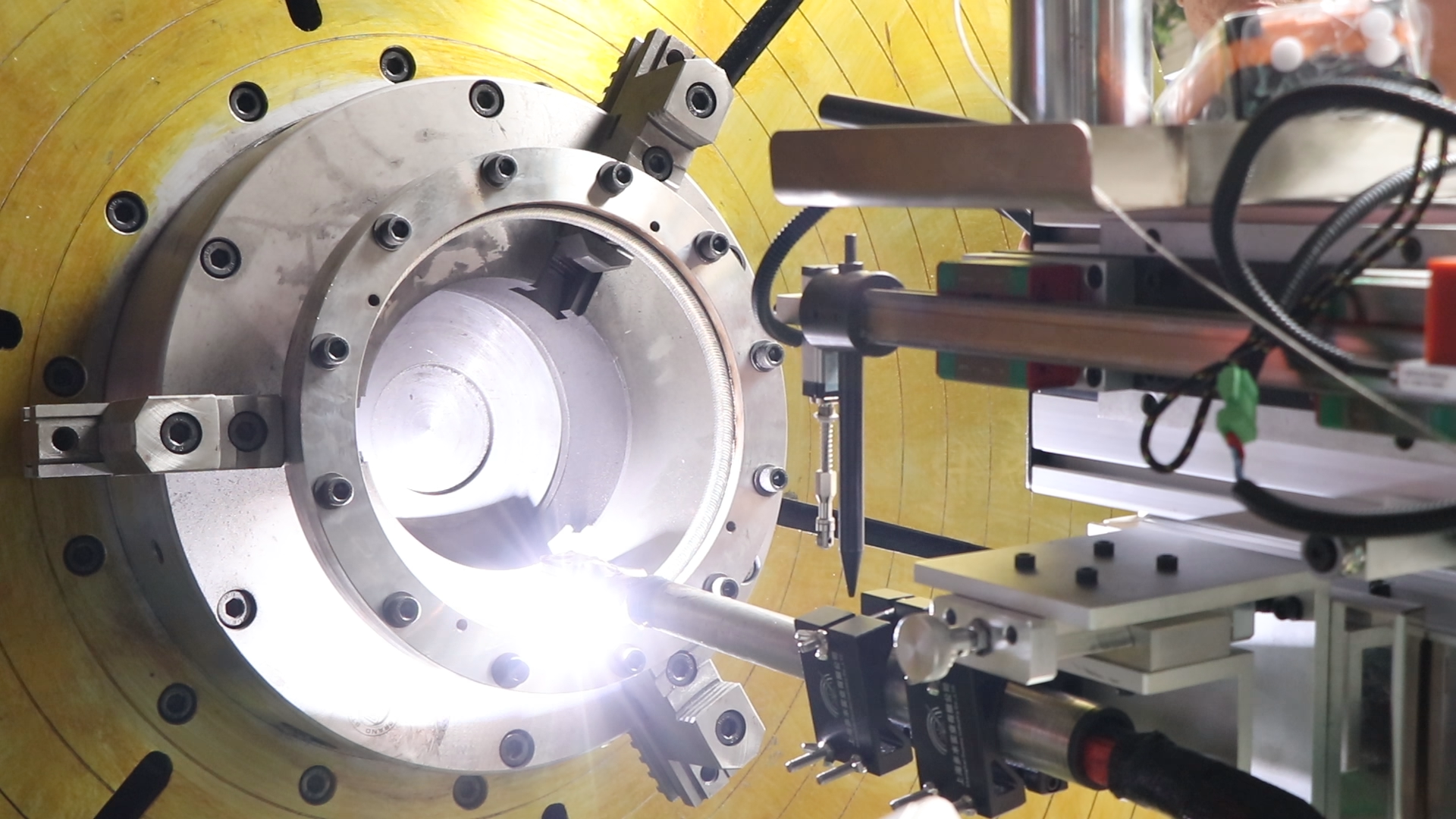

Processus soldadurae PTA pro superficiebus obturantibus valvulae tripliciter eccentricae

1. Praeparatio superficiei: Superficiem obturantem munda et maculas olei, rubiginem, et strata oxidationis remove.

2. Positio et prehensio: Fac ut materia accurate fixa sit in apparatu CNC vel machina soldadurae speciali.

3. Soldatura PTA: Parametros sicut fluxum soldaturae, celeritatem pulveris alimentationis, et celeritatem soldaturae secundum materiam valvulae et proprietates pulveris constitue.

4. Refrigeratio et purgatio: Celeritatem refrigerationis modera et aspersionem superficialem remove.

5. Machinatio et trituratio: Accurationem dimensionalem et asperitatem superficiei obsignantis restitue.

6. Inspectio qualitatis: Complectitur probationem duritiae, probationem penetrantis, et verificationem effectus obsignationis.

Cur soldadura PTA ad valvas triplices eccentricas reparandas eligendum est?

Soldatura arcus plasmatis per translationem solutionem magnae efficaciae et diuturnam praebet ad superficies obturantes valvularum tripliciter eccentricarum fabricandas et reparandas. Non solum dimensiones et efficaciam superficiei obturantis restituit, sed etiam resistentiam eius contra detritionem, corrosionem et erosionem insigniter auget.

Plura de modis quibus arcus plasmatis per soldaduram valvulas triplices eccentricas reparare possit scire cupientes, vel de necessitatibus tuis reparationis specificis disserere,nobis inscriptionem electronicam mitte! Turma nostra peritorum parata est solutiones aptatas pro applicatione tua specifica praebere.

Tempus publicationis: XV Augusti, MMXXXV